4TU.HTM & M2i Joint Workshop

** This event took place already **

The 4TU.Research Centre High-Tech Materials and the Materials innovation institute (M2i) jointly organized a series of online lectures on Artificial Intelligence in Materials Science on Wednesday June 16th and Wednesday June 23rd, 2021.

Programme

Here you can find the full programme (Pdf file).

Artificial Intelligence in Materials Science

Artificial Intelligence (A.I.) has grown into a major tool of scientific and technological importance and impact. Its huge potential to optimise design, production and application of materials attracts more and more interest from materials scientists. Amongst other aspects, participants in this workshop are encouraged to explore the huge potential of A.I. in combination with physics.

Aim

The workshop provides reviews and examples of present and future applications of Artificial Intelligence in materials science and engineering for a range of materials and with an emphasis on sustainability. The speakers are presented below in no particular order.

Prof.dr.ing. Bojana Rosic

Head of the Applied Mechanics & Data Analysis group, Faculty of Engineering Technology, University of Twente. Her research interest lies in an interplay of nonlinear mechanics/structural dynamics modelling and the development of machine learning techniques with the focus on the predictive modelling of systems, processes and materials, and their assimilation with the measurement data (Digital Twin/AI).

Head of the Applied Mechanics & Data Analysis group, Faculty of Engineering Technology, University of Twente. Her research interest lies in an interplay of nonlinear mechanics/structural dynamics modelling and the development of machine learning techniques with the focus on the predictive modelling of systems, processes and materials, and their assimilation with the measurement data (Digital Twin/AI).

Key words: uncertainty, modelling, deep learning

Abstract

Today many industrial applications require real time models that are able to accurately predict behaviour of nonlinear dynamical/quasi-static systems. Due to the presence of uncertainties in the model description and lack of big data sets, the use of stochastic physics-based models on both hierarchical material [1] and system levels [2] are often considered computationally too ambitious for model predictive control purposes, predictive maintenance and often for the engineering inverse design. In addition, the functional approximation of non-Gaussian distributions in a high dimensional parametric space is challenging, if not impossible. Under newly developed concept of deep learning, the different physics-based models can be treated in a unified manner. However, these models are often over-parametrized, require fine tuning, and are not constrained by physics [3]. In this talk, the stochastic nonlinear models will be considered in a stochastic deep/machine learning setting that takes the physics into account, as well as optimal network architecture [2,4,5]. In this talk, a few examples based on the research works in Applied Mechanics and Data Analysis groups will be presented.

References

- M. Sarfaraz, B. Rosić, H. Matthies, A Ibrahimbegović. Bayesian stochastic multi-scale analysis via energy considerations. Advanced Modeling and Simulation in Engineering Sciences 7 (1, 2020), 1-35. https://doi.org/10.1186/s40323-020-00185-y

- B. Rosic. Stochastic state estimation via incremental sparse polynomial chaos based Bayesian-Gauss-Newton-Markov-Kalman filter, arXiv preprint arXiv:1909.07209

- B. van de Weg, L. Greve, M. Andres, T. Eller, B. Rosic, Neural network-based surrogate model for a bifurcating structural fracture response, Engineering Fracture Mechanics 241, 107424. https://doi.org/10.1016/j.engfracmech.2020.107424

- B. van de Weg, L. Greve, B. Rosic. Long short term relevance learning. To be published on Arxiv.

- S. Shivanand and B. Rosic. Scale-invariant multi-level Monte Carlo method. To be published on Arxiv.

Dr. Miguel Bessa

Associate Professor in the Department of Materials Science and Engineering, 3mE, Delft University of Technology with research interests in computational mechanics and materials science: development of numerical methods, machine learning and optimization, multi-scale modeling of materials and structures.

Abstract

Nanomechanical resonators are key enablers of next-generation technologies: from ultra-sensitive detectors of fundamental forces, to quantum-limited commercial sensors and quantum networks operating at room temperature. Yet, rational design of nanomechanical resonators is far from trivial. Apart from basic principles derived from one-dimensional analytical models and the broad use of the same high-tensile material (silicon nitride), human intuition remains the driving force of the design process. Here, inspired by nature and guided by machine learning, a new spider web-like resonator concept is created that exhibits a novel vibration mode that eliminates radiation losses without using phononic shields. This vibration mode was not expected prior to the data-driven exploration but it was found to be essential in obtaining an unprecedented quality factor (over 1 billion) at low frequencies (less than 150 kHz). This work demonstrates that data-scarce machine learning algorithms such as Bayesian optimization can play a key role in exploring new directions in nanotechnology.

Personal website: https://mabessa.github.io/

Twitter: @MiguelABessa

Dr. Ondrej Rokos

Assistant Professor in the Mechanics of Materials section of the Department of Mechanical Engineering of Eindhoven University of Technology.

Assistant Professor in the Mechanics of Materials section of the Department of Mechanical Engineering of Eindhoven University of Technology.

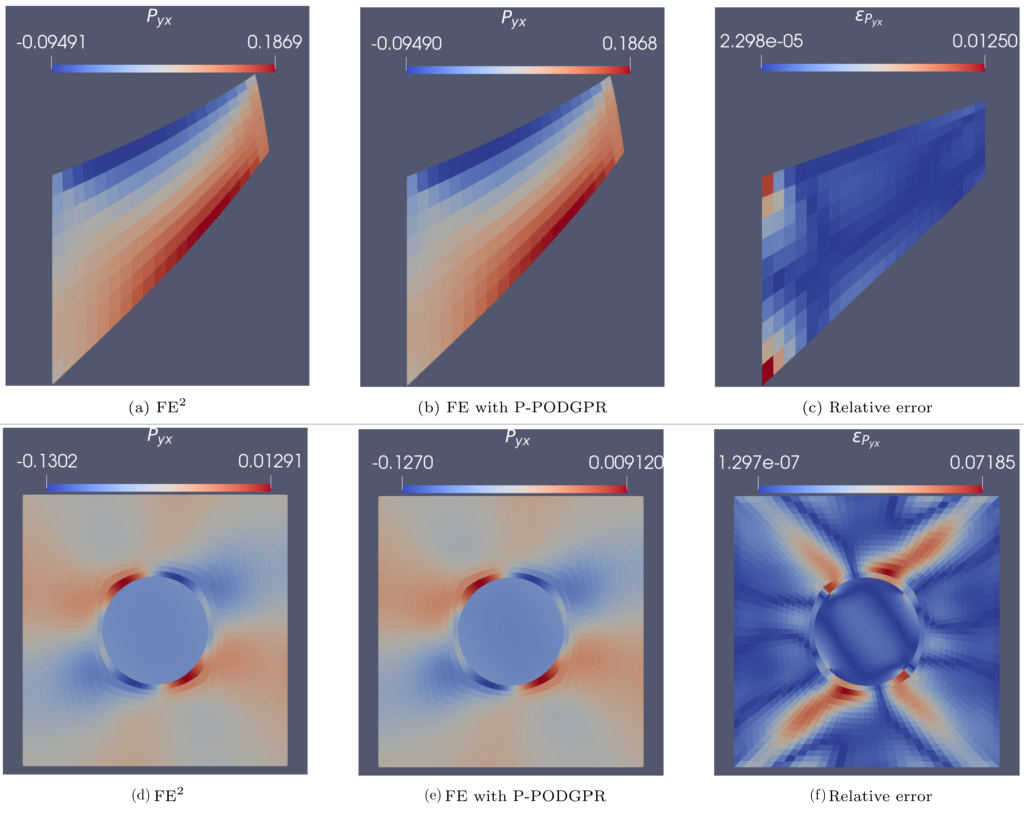

Key words: Non-intrusive reduced basis method, proper orthogonal decomposition, computational homogenization, Gaussian process regression, multiscale analysis

Abstract

Determination of effective constitutive models of materials with heterogeneous microstructures is a challenging and computationally intensive task, especially when instabilities, non-linearity, or multiphysics emerge at the microscale. Yet, effective models are a crucial component in the design of materials that perform optimally in their target applications through careful tailoring of their microstructural features.

To address these issues, we introduce as first steps a non-intrusive reduced basis method to construct inexpensive surrogates for parametrized microscale problems. The method is specifically well-suited for multiscale simulations, since the coupled simulation is decoupled into two independent problems: (1) solving the microscopic problem for different (loading or material) parameters and learning a surrogate model from the data, and (2) solving the macroscopic problem with the learned material model. The proposed method has three key features: (i) the microscopic stress field can be fully recovered, (ii) the method is able to accurately predict the stress field for a wide range of material parameters, and (iii) the derivatives of the effective stress with respect to the material parameters are available and can be readily utilized in solving optimization problems. Extensions towards inversion of surrogates and exploration of available design space is finally briefly outlined and discussed.

References

- T. Guo, O. Rokoš, and K. Veroy, “Learning constitutive models from microstructural simulations via a non-intrusive reduced basis method,” Comput. Methods Appl. Mech. Eng., vol. 384, p. 113924, Oct. 2021. https://arxiv.org/abs/2104.04451

Image: Comparison between full FE2 (left column), FE with learnt model (middle column), and relative error between the two (right column). Top row corresponds to macroscopic domain (Cook's membrane), whereas bottom to a single chosen representative RVE.

Image: Comparison between full FE2 (left column), FE with learnt model (middle column), and relative error between the two (right column). Top row corresponds to macroscopic domain (Cook's membrane), whereas bottom to a single chosen representative RVE.

Dr. Laura Filion

Associate Professor in the Soft Condensed Matter group, Debye Institute for Nanomaterials Science, Utrecht University, where they study the self-organization of colloidal particles using computer simulations.

Associate Professor in the Soft Condensed Matter group, Debye Institute for Nanomaterials Science, Utrecht University, where they study the self-organization of colloidal particles using computer simulations.

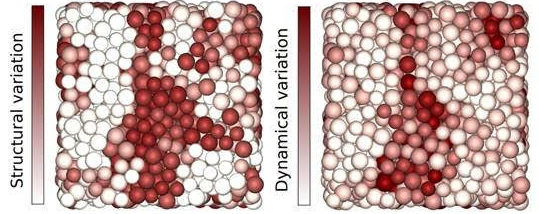

Key words: glasses, order parameters, soft matter, colloids, computer simulations

Abstract

Developments in machine learning have opened the door to fully new methods for studying phase transitions due to their ability to extremely efficiently identify complex patterns in systems of many particles. Applications of machine learning techniques vary from the use of developing new ML-based order parameters for complex crystal structures, to locating phase transitions, to speeding up simulations. The rapid emergence of multiple applications of machine learning to statistical mechanics and materials science demonstrates that these techniques are destined to become an important tool for soft matter physics. In this talk, I will briefly present an overview of the work my group is doing on using ML to study soft matter systems, with a focus on a new application in the field of glassy materials. Specifically, I will present a new unsupervised algorithm developed in my group that can find structural variations in glassy materials that turn out to correlate strongly with local dynamics.

References

- Autonomously revealing hidden local structures in supercooled liquids. Emanuele Boattini, Susana Marín-Aguilar, Saheli Mitra, Giuseppe Foffi, Frank Smallenburg and Laura Filion. Nat. Commun. 11 (2020), 5479. https://doi.org/10.1038/s41467-020-19286-8

Image: Comparison between ML structural order parameter (left) and measured dynamics (right)

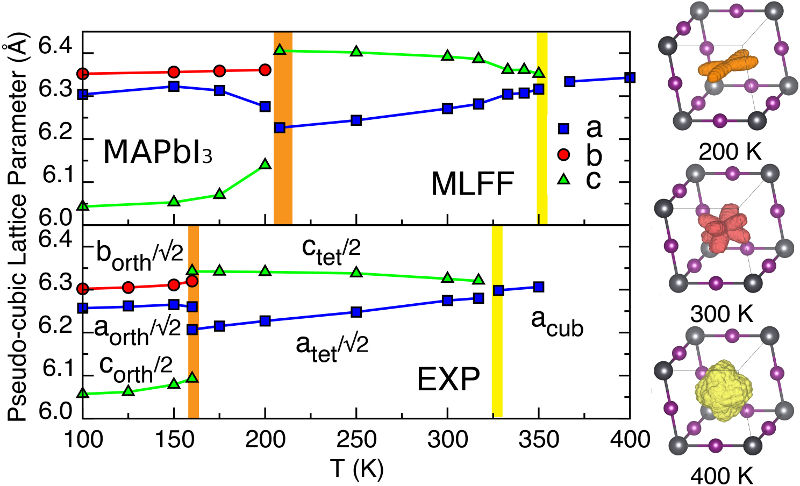

Dr.ir. Menno Bokdam

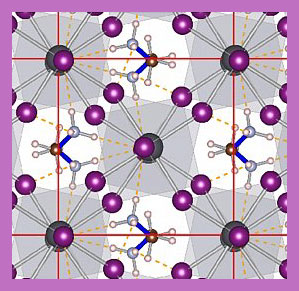

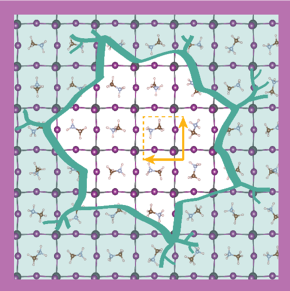

Assistant professor in the Computational Materials Science group, Faculty of Science and Technology and MESA+ Institute for Nanotechnology, University of Twente, with research interests in codensed matter physics, machine-learning force fields, electronic structure, computational materials science, mixed hybrid perovskites, dynamic solids, phonons, thermalconductivity.

Abstract

Lattice dynamics at the atomic scale is often well described by phonons in the harmonic approximation. However, it does not always suffice. For example, it does not explain crystals with ultra-low thermal conductivities or phase transitions. While a more accurate method, ab-initio molecular-dynamics (MD), captures the anharmonicity of the atomic interactions correctly, it is computationally orders of magnitude too expensive to describe the effects of phonon scattering related to the "rattling" and "flipping" of atoms and molecules. We recently developed a novel method that can account for these effects based on an on-the-fly Machine-Learning Force-Field (MLFF) approach [1]. It allows us to automatically ‘train’ smooth and ‘cheap’ models of the potential energy surface based on density functional theory calculations. The MLFF gives access to the nanosecond time- and tens of nanometer length-scales and opens up the possibility to predict complex phase transitions, capture the formation and breaking of weak bonds and ion diffusion, simulate lattice thermal conductivity and NMR dipolar coupling[2] in complex ‘dynamic solids’.

Image: Phase transitions in complex solids (www.dynamicsolids.net)

References

- Jinnouchi R., Lahnsteiner J., Karsai F., Kresse G., Bokdam M., "Phase transitions of hybrid perovskites simulated by machine-learning force fields trained on the fly with Bayesian inference", Phys. Rev. Lett. 122, 225701 (2019). https://doi.org/10.1103/PhysRevLett.122.225701

- Grueninger H., Bokdam M.; Leupold N.; Tinnemans P., Moos R., De Wijs G., Panzer F. and Kentgens A., "Microscopic (dis)order and dynamics of cations in mixed FA/MA lead halide perovskites", J. Phys. Chem. C, 125, 1742-1753 (2021). https://doi.org/10.1021/acs.jpcc.0c10042

Personal website of dr.ir. Menno Bokdam: www.dynamicsolids.net

Dr. Dimitrios Zarouchas

Assistant Professor Artificial Intelligence for Structures, Prognostics & Health Management, in the Structural Integrity & Composites group of the Department of Aerospace Structures & Materials, Faculty of Aerospace Engineering, Delft University of Technology.

Assistant Professor Artificial Intelligence for Structures, Prognostics & Health Management, in the Structural Integrity & Composites group of the Department of Aerospace Structures & Materials, Faculty of Aerospace Engineering, Delft University of Technology.

Abstract

Aerospace structures usually operate in non-uniform environments and altering operational conditions e.g. loads, temperature, humidity. The structure’s life is heavily influenced by the way it is operated, maintained, the environmental and operation conditions, which are not always the designed ones, because unexpected phenomena can be occurred during the structure’s lifetime. Foreign objects impacts, such as bird-strikes or hail may occur anytime during the lifetime of the aircraft. These events fail into category of unexpected phenomena that may create damage, which may have not been anticipated into the design phase. The implication is to interrupt the aircraft operation and initiate inspection and repair actions resulting to unplanned costs. In this case, the role of a remaining useful life prediction approach would be to assess the effect of the unexpected event and to provide an updated prediction. We propose a new data-driven prognostic approach that is capable of real-time learning and adapting the estimated parameters of a degradation model based on the availability of real-time data and the diagnostic measures at the moment that the unexpected phenomenon occurs.

References

- An adaptive probabilistic data-driven methodology for prognosis of the fatigue life of composite structures. Nick Eleftheroglou, Dimitrios Zarouchas, Rinze Benedictus, Composite Structures, vol. 245, 112386. https://doi.org/10.1016/j.compstruct.2020.112386

- Structural health monitoring data fusion for in-situ life prognosis of composite structures. Nick Eleftheroglou, Dimitrios Zarouchas, Theodoros Loutas, Rene Alderliesten, Rinze Benedictus, Reliability Engineering & System Safety, vol. 178, pp. 40-54. https://doi.org/10.1016/j.ress.2018.04.031

Photo: Set-up (TU Delft)

Within this framework dr. Dimitrios Zarouchas has a research interest in: health state adaptation, probabilistic data-driven methodology, structural health monitoring, machine learning

Personal website: http://dimitrioszarouchas.com

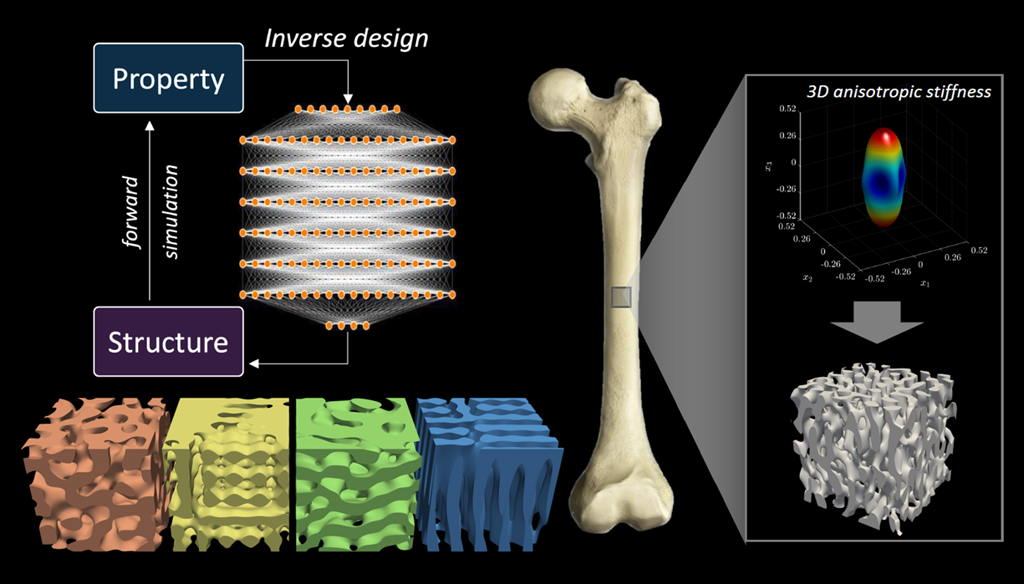

Dr. Sid Kumar

Assistant Professor in the department of Materials Science and Engineering, 3mE, Delft University of Technology, with a research interest in the intersection of materials science, mechanics and machine learning.

Assistant Professor in the department of Materials Science and Engineering, 3mE, Delft University of Technology, with a research interest in the intersection of materials science, mechanics and machine learning.

Abstract

Structure-property relations of all existing (meta-)materials have primarily been explored in a forward fashion: given a design or microstructure, one extracts the effective properties by methods of homogenization. The inverse challenge – identifying a microstructural topology that meets the mechanical property requirements – has often been addressed by inefficient trial and error. In addition, while the forward problem, i.e., mapping from topological parameters to property space, is well-defined, the inverse problem is ill-posed (multiple topologies can have the same or similar effective properties).

To address the inverse challenge of identifying a (meta-)material topology from a huge design space to achieve target or novel properties, we introduce a novel data-driven approach based on the integration of two neural networks for the forward- and inverse-problems that renders the inverse design challenge well-posed. We demonstrate how the framework of machine-learning-driven inverse design can reliably and accurately generate foam- and truss-type cellular metamaterials with as-designed 3D anisotropy and density in a spatially uniform or functionally graded fashion. As an example, we highlight the suitability of such inverse-designed metamaterials for the generation of bio-mimetic and patient-specific bone implants and tissue scaffolds.

References

- S. Kumar, S. Tan, L. Zheng, D. M. Kochmann, Inverse-designed spinodoid metamaterials, npj Computational Materials, 6 (2020), 73. https://www.nature.com/articles/s41524-020-0341-6

- L. Zheng, S. Kumar, D. M. Kochmann, Data-driven topology optimization of spinodoid metamaterials with seamlessly tunable anisotropy, Computer Methods in Applied Mechanics and Engineering, 383 (2021), 113894. https://doi.org/10.1016/j.cma.2021.113894

Image: Designing metamaterials with artificial intelligence

Image: Designing metamaterials with artificial intelligence

Dr. Sid Kumar has a research interest in the intersection of materials science, mechanics and machine learning. Key words: Materials by design, Inverse design, Metamaterials, Architected materials, Machine learning.

Personal website: https://www.sid-kumar.com/

Twitter: @sidkumar_mech

Chairs

Prof.dr.ir. Jilt Sietsma

Prof.dr.ir. Jilt Sietsma

Scientific director 4TU.HTM, Full professor Materials Science and Engineering (Microstructures), Mechanical, Maritime and Materials Engineering, Delft University of Technology.

Key words: metalic microstructures, metallurgy, steel

Chair on the 16th of June.

Dr. Marcel Sluiter

Associate professor Materials Science and Engineering (Computational), Mechanical, Maritime and Materials Engineering, Delft University of Technology and visiting professor in the Department of Electromechanical, Systems and Metal Engineering (Microstructures of Materials), Faculty of Engineering and Architecture, Ghent University.

Research interests: computational materials science, thermodynamics & kinetics, phase transformations, prediction of materials properties

Chair on the 23rd of June.

For more information, contact Reina Boerrigter (coordinator 4TU.HTM)