Circular & Sustainable Materials in 2050

This workshop Joint 4TU.HTM workshop in close collaboration with the Materials innovation institute (M2i) and the Leiden-Delft-Erasmus Centre for Sustainability took place on 20 January 2022. All information can be found below.

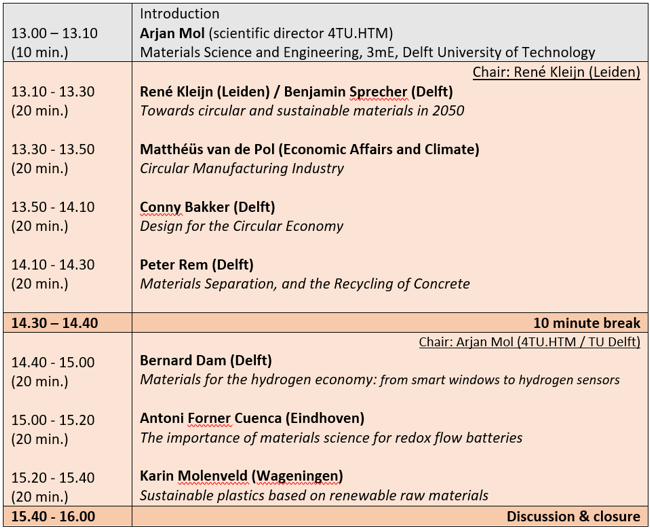

Programme

Aim of the workshop

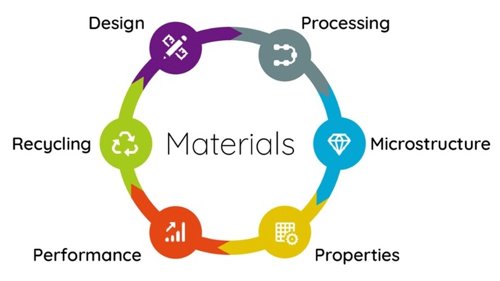

A sustainable future requires not only an energy transition, but also a materials transition in the coming three decades. The transition towards sustainable production and consumption of materials, over the whole materials life cycle, requires huge investments, fundamental and applied research and technology development, as well as political and societal support and motivation. Materials science and engineering will play a crucial role in developing the technologies and materials that are needed to achieve a transition to a carbon neutral and circular society.

A sustainable future requires not only an energy transition, but also a materials transition in the coming three decades. The transition towards sustainable production and consumption of materials, over the whole materials life cycle, requires huge investments, fundamental and applied research and technology development, as well as political and societal support and motivation. Materials science and engineering will play a crucial role in developing the technologies and materials that are needed to achieve a transition to a carbon neutral and circular society.

In this joint workshop 4TU.HTM, M2i and the LDE Centre for Sustainability aim to bring together a wide range of scientists to share their knowledge on what this future society will look like and how materials science and engineering can help to achieve a sustainable future. We aim to increase awareness of the importance of materials amongst colleagues and students from relevant scientific fields. Therefore, we invite everyone to attend this workshop, which will be held online.

Prof.dr.ir. Arjan Mol

Scientific Director of 4TU.HTM, Professor Corrosion Technology & Electrochemistry, Materials Science & Engineering, TU Delft

Dr. René Kleijn

Associate Professor Industrial Ecology, Institute of Environmental Studies, Leiden University / LDE Centre for Sustainability

Associate Professor Industrial Ecology, Institute of Environmental Studies, Leiden University / LDE Centre for Sustainability

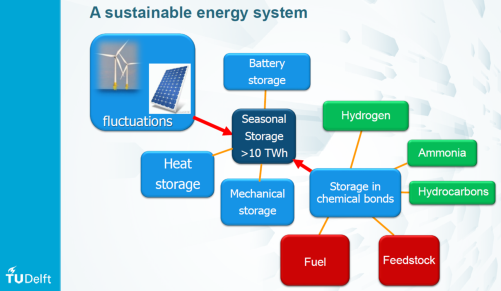

The main research interests of René Kleijn are critical materials, material constraints and resilient material supply chains as well as lo-carbon energy technologies. He focusses on the development of industrial ecology tools like (dynamic) Substance Flow Analysis (SFA), Material Flow Accounting (MFA) and Life Cycle Assessment (LCA). Currently the most important case studies are on the material constraints of novel (energy) technologies, circular economy, eco-innovation and resilient supply chains.

Together with dr. Benjamin Sprecher he will address the topic:

Towards circular and sustainable materials in 2050

Dr. Benjamin Sprecher

Assistant Professor Industrial Design Engineering, Design for Sustainability, Delft University of Technology

Assistant Professor Industrial Design Engineering, Design for Sustainability, Delft University of Technology

Benjamin works on linking decision making on the design level to higher level goals such as circular economy and climate change. He has a special interest in the role of critical materials and how these relate to transitions such as the energy transition.

Reference

Sprecher, Benjamin, and Rene Kleijn. "Tackling material constraints on the exponential growth of the energy transition." One Earth 4.3 (2021): 335-338. https://doi.org/10.1016/j.oneear.2021.02.020

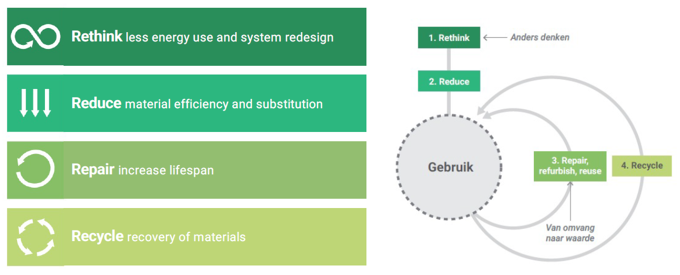

Image: Four circular strategies

Matthéüs van de Pol

Program leader Circular Manufacturing Industry, Ministry of Economic Affairs and Climate

Circular Manufacturing Industry

More general information on the 'Circulaire Maakindustrie' - and for more focus: Short term information.

Also available on this website, an interview (in Dutch) with the previous speaker, dr. Benjamin Sprecher (TU Delft).

Prof.dr.ir. Conny Bakker

Professor of Design Methodology for Sustainability and Circular Economy, Faculty of Industrial Design Engineering, Delft University of Technology

Professor of Design Methodology for Sustainability and Circular Economy, Faculty of Industrial Design Engineering, Delft University of Technology

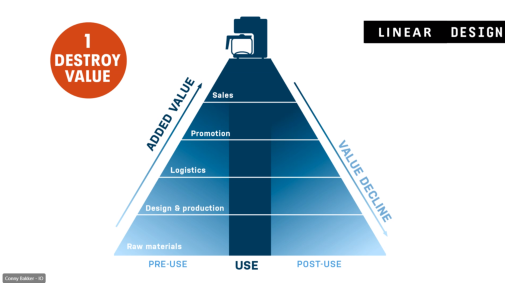

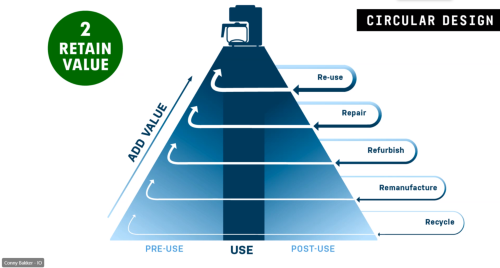

Design for the Circular Economy

Her research field is the development of design methods for products that have multiple lifecycles. She explores strategies such as product lifetime extension, reuse, remanufacturing and recycling, and the business models that enable these strategies. Conny co-leads the European H2020 project ReCiPSS, that helps designers and manufacturers understand how collection, remanufacturing and reuse of products can lead to more profitable, resource-efficient and resilient business practices. She coordinates and teaches several courses in Sustainable Design and Design for the Circular Economy, including a popular MOOC (Massive Open Online Course) which has attracted over 50,000 learners so far.

Further info: Publications by Conny Bakker.

Prof.dr. Peter Rem

Professor in the Resources & Recycling Section, Faculty of Civil Engineering and Geosciences, Delft University of Technolog

Professor in the Resources & Recycling Section, Faculty of Civil Engineering and Geosciences, Delft University of Technolog

The reserearch interests of Peter Rem are modes of behavior of complex systems in physics, electromagnetics and fluid dynamics, separation science & technology, and the societal transition towards circularity.

Materials Separation, and the Recycling of Concrete

Abstract

The explosive demand for primary raw materials and materials science in the first half of the previous century inspired physicists to study beautiful new systems in physics and mathematics. Now, the need to switch from primary sources to recycled materials from waste creates a new range of fundamental problems in science with exciting new phenomena. Some examples are presented; a mathematical problem from the research on purifying polymers from mixtures of thousands of different types in packaging waste, and two physics problems from the recycling of concrete. The solution of the last two resulted in the 2021 EU Innovation Radar Prize for Sustainable Tech (https://www.innoradar.eu/innoradarprize).

Referecences

- van Engelshoven, Y., Wen, P., Bakker, M., Balkenende, R., Rem, P. An innovative route to circular rigid plastics (2019) Sustainability, 11 (22). https://doi.org/10.3390/su11226284

- Di Maio, F., Rem, P.C., Baldé, K., Polder, M. Measuring resource efficiency and circular economy: A market value approach (2017) Resources, Conservation and Recycling, 122, pp. 163-171. https://doi.org/10.1016/j.resconrec.2017.02.009

Prof.dr. Bernard Dam

Professor at the Department of Chemical Engineering, Faculty of Applied Sciences, Delft University of Technology

Professor at the Department of Chemical Engineering, Faculty of Applied Sciences, Delft University of Technology

Materials for the hydrogen economy: from smart windows to hydrogen sensors

His field is functional thin film materials science: find relations between growth, (defect)structure and physical properties in relation to their application. At present we investigate metal hydride based hydrogen sensors, chemochromic windows and hydride-based solid state electrolytes.

Source: Delft University of Technology

Dr. Antoni Forner Cuenca

Assistant Professor in the Membrane Materials and Processes Group at the Department of Chemical Engineering and Chemistry, Eindhoven University of Technology.

Assistant Professor in the Membrane Materials and Processes Group at the Department of Chemical Engineering and Chemistry, Eindhoven University of Technology.

The importance of materials science for redox flow batteries

Redox flow batteries (RFBs) are promising rechargeable electrochemical devices for grid-scale energy storage, but further cost reductions are needed for widespread implementation. While research efforts have primarily focused on molecular discovery, there has been significantly less attention paid to the engineering aspects (i.e. transport phenomena, reactor design) of the battery. Of particular importance are the porous electrodes used in the electrochemical stack, which are typically made of carbon fibers arranged in various structures. Today’s electrodes largely draw from the fuel cell material set, but, within a RFB, the porous electrode must perform a number of different roles including providing active surfaces for electrochemical reactions, facilitating uniform liquid electrolyte distribution, and supporting low pressure drops.

Forner-Cuenca Lab

Follow Antoni Forner Cuenca on Twitter: @AntoniForner

Ir. Karin Molenveld

Senior Scientist Biopolymers, Wageningen Food & Biobased Research, Wageningen University & Research

Senior Scientist Biopolymers, Wageningen Food & Biobased Research, Wageningen University & Research

Sustainable plastics based on renewable raw materials

Karin Molenveld is educated as a Chemical Engineer (MsC) at the Technical University of Twente. She has been working at Wageningen Food & Biobased Research in the field of sustainable plastics for over 25 years. At present Karin is expertise leader in the field of “Sustainable Plastic Technology” coordinating the work of a group of about 20 people focussed on topics related to the development and application of biobased and biodegradable plastics and the end-of-life of plastic products including organic, chemical and mechanical recycling.

Extending the application opportunities of biobased and biodegradable plastics as well improving recycling practices of plastic products are the main topics within this expertise. Well known examples of developed products include PLA based particle foam (Biofoam™), full PLA coffee cups as well as various starch based compounds and products. More recent topics include biodegradable netting for agricultural applications, the fate of compostable products in full scale organic waste treatment facilities and improving the properties of PLA with respect to its foaming behaviour, flow properties and biodegradation in the open environment. More generic topics are the effect of regulations on recyclability of packaging, the ban on single use plastics and balancing the use of packaging with food waste prevention.

Source: Wageningen University & Research

Header picture: solar fuels plasma reactor for efficient recycling of CO2 into building blocks for sustainable fuel (DIFFER)