4TU.HTM & M2i Joint Workshop

Most of the presentations of the jointly organized workshop Surfaces, Interfaces & Coatings are availabe at this event page of the 4TU.HTM website.

Programme

The programme included speakers from universities and industry.

Full programme (Pdf file)

Surfaces, Interfaces & Coatings

Every material, also if applied for its bulk properties, has a surface or at least an interface to another material, where numerous dynamic processes can take place, down to the smallest length scales. These processes can form a threat for the material (like corrosion), but can also be beneficial or even essential for its functionality (like heat exchange). Coatings, introducing new surfaces and interfaces, can form an effective means to improve the functionality and/or life time of materials. Understanding surfaces and interfaces forms an intricate and essential part of materials science in its quest to optimise understanding and application of materials.

Aim

This workshop aims to bring together scientists and industrial partners with interest and expertise in surfaces, interfaces and coatings throughout the different types of materials, techniques and processes for an exchange of ideas and observations.

Confirmed speakers

Thursday 22 October 2020 (this session took place already)

15.00 - 17.00 hours

Dr. Alejandro Aregón (TU Delft)

Assistant Professor Structural Optimization and Mechanics, Department Precision and Microsystems Engineering (PME), 3mE, Delft University of Technology

Assistant Professor Structural Optimization and Mechanics, Department Precision and Microsystems Engineering (PME), 3mE, Delft University of Technology

Title: Enriched finite element modelling of interface problems - Presentation (Pdf file)

Abstract (short version)

This presentation delves into the computational modeling of problems containing interfaces. It is shown that enriched FEM can be used to solve problems with complex morphologies by using simple structured FE discretizations.

The full abstract (including figures and references) can be found here (Pdf file).

Prof.dr.ir. Matthijn de Rooij (UTwente)

Professor Surface Engineering and Maintenance, Department Mechanics of Solids, Surfaces & Systems (MS3), Faculty of Engineering Technology, University of Twente

Professor Surface Engineering and Maintenance, Department Mechanics of Solids, Surfaces & Systems (MS3), Faculty of Engineering Technology, University of Twente

Title: Modelling and measuring adhesion and friction in a tribological contact - Presentation (Pdf file)

Abstract

Friction is contacts that operate in a vacuum environment is to a large extent determined by the roughness details of the surface as well as the surface forces acting in the interface. A boundary element model has been developed to calculate the pre-sliding distance as well adhesion forces in a rough interface, based on the acting van der Waals as well as meniscus forcesComparing models with accurate measurements of adhesion force and pre-sliding distance, it can be concluded that model results are in good agreement with the experimental values.

Dr. Amarante Böttger (TU Delft, Avans Hogeschool)

Associate Professor Materials Science and Engineering (3mE, TU Delft) and Professor New Materials and Applications (Avans Hogeschool)

Associate Professor Materials Science and Engineering (3mE, TU Delft) and Professor New Materials and Applications (Avans Hogeschool)

Title: Modelling of surface segregation for palladium alloys in vacuum and gas environments - Presentation (Pdf)

Abstract

Ternary alloys have been developed for a wide range of applications and in many cases surface segregation of ternary alloys has a decisive impact on their performance, especially on the corrosion, adsorption and catalytic properties. Different from binary alloys, in which surface energy is usually the dominant factor for surface segregation, the interaction between solute elements has a noticeable effect on the surface segregation behaviour of ternary alloys. In the present work, surface segregation of Pd-based ternary alloys (Pd-Cu-Mo), Pd-Cu-Ag) in both vacuum and hydrogen atmosphere was investigated. XPS and LEISS analyses revealed that the segregation trend of the outermost atomic layer is not always the same as that of the near-surface-region. A thermodynamic model was developed to describe the surface segregation of ternary alloys. The results of the model are in qualitative agreement with the experimental results. Calculations for other ternary alloy systems confirmed that the model provides a simple but universal method for predicting surface segregation in ternary alloys. (https://doi.org/10.1016/j.ijhydene.2017.12.039)

Dr. Sissi de Beer (UTwente)

Faculty of Science and Technology, Sustainable Polymer Chemistry group, University of Twente

Faculty of Science and Technology, Sustainable Polymer Chemistry group, University of Twente

Title: Modelling polymer brush coatings in contact with gasses for sensor and separation technologies - Presentation (Pdf)

Abstract

Coatings composed of polymer brushes can give advanced functionality to surfaces and enable sensitive sensing or advanced separations. For these applications, it is important to understand the sorption characteristics of brushes in contact with different vapors. In this presentation, I will provide theoretical equations and a microscopic model for vapor sorption in polymer brushes and compare them to experimental observations.

https://pubs.acs.org/doi/abs/10.1021/acs.macromol.0c01637

Thursday 29 October 2020 (this session took place already)

15.00 - 17.00 hours

Arnoud de Vooys (Tata Steel R&D)

Principal Scientist at Tata Steel Research & Development

Principal Scientist at Tata Steel Research & Development

Title: Trivalent chromium plating in a high-speed continuous steel strip plating line - Presentation (not available yet)

Abstract

ECCS (‘Electrolytic Chromium Coated Steel’) is packaging steel with a very thin coating comprising a Cr‑metal (50-100 mg m‑2) base layer and a Cr‑oxide (7-35 mg m‑2) top layer. The oxide layer ensures good adhesion with lacquers and polymer coatings (PET, PP). ECCS is used for numerous applications, such as Easy Open Ends, Twist-Off Caps, Crown Caps, and Two-Piece Cans. ECCS is produced in continuous electroplating lines, in which steel strip is transported at high speed through a number of plating cells. The fast movement of the steel strip causes a lot of turbulence resulting in high mass transfer. The deposition process is typically completed within a few seconds. ECCS is produced from electrolytes, which contain chromic acid. Chromium(VI), however, is harmful to the environment and poses a risk to the health of workers. In response to REACH legislation banning the use of chromium(VI), Tata Steel has developed a new process based on safe chromium(III) to replace ECCS. This presentation is about the development of this new process called TCCT® (Trivalent Chromium-Coating Technology).

- Electrodeposition of mixed chromium metal-carbide-oxide coatings from a trivalent chromium-formate electrolyte without a buffering agent (Electrochimica Acta, 173, 819-826, 2015)

- Oxidation reactions in chromium(III) formate electrolytes at platinum and at a catalytic mixed metal oxide coating of iridium oxide and tantalum oxide (Electrochimica Acta, 213, 194-200, 2016)

- Cyclic voltammetry study of trivalent basic chromium sulphate electrolytes contaminated with sulphite (Electrochimica Acta, 269, 700-705, 2018)

Dr. Lie Zhao (VDL Weweler BV)

Senior Process Engineer,

VDL Weweler BV (Apeldoorn, the Netherlands)

Title: Surface development of trailing arms during fully automatic production: challenge and innovation - Presentation (Pdf)

Abstract

- Surface quality is essential for our product: almost all fatigue cracks were initiated from the surface.

- High temperature decarburization and oxidation during production are inevitable but have to be properly handled.

- Carburization is almost impossible for fully automatic production line: a new challenge.

- Shot peening plays an important role to improve the surface quality.

- Coating with epoxy paint and novel Zinc coating technology (sherardizing)

Dr. Lie Zhao studied Metallic Materials at Zhejiang University in China and received his Ph.D at the University of Twente, the Netherlands in 1997. From 1998 till 2013, he worked at Delft University of Technology and M2i (Materials Innovation Institute), first as a postdoctoral researcher and later as a research fellow. His research interests comprise various steels: TRIP steels, TWIP steel, Q&P steels, bearing steels and spring steels. In 2013 he joined VDL Weweler BV as a senior process engineer. He worked on the setup of materials and product requirements in executable processes and manageable standards, the improvement of the existing process and the introduction of new processing routes.

Ir. Ingmar van Hengel (TU Delft)

PhD candiate Biomaterials & Tissue Biomechanics, Departement of Biomechanical Engineering, 3mE, Delft University of Technology

PhD candiate Biomaterials & Tissue Biomechanics, Departement of Biomechanical Engineering, 3mE, Delft University of Technology

Title: Additively manufactured implants with multifunctional surfaces - Presentation (Pdf)

Abstract

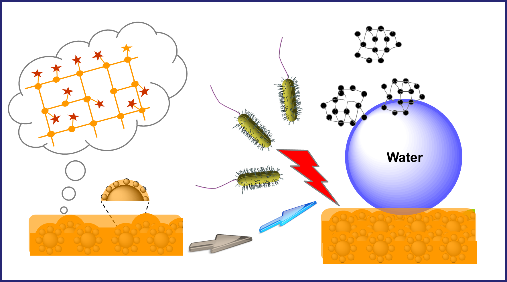

We all know someone who received a hip or knee implant. Together with the number of implants, the number of complications is on the rise: implant-associated infections and implant loosening have great impact on quality of life and functioning in society. We aim to prevent these complications by fabricating multifunctional bone implants through a combination of rational design, additive manufacturing and surface biofunctionalization.

Also look at the college Ingmar van Hengel and his colleague Sebastien Callens gave in the Universiteit van Nederland series called 'Machtige Materialen'.

Wat hebben Japanse origami en botimplantaten met elkaar gemeen? (YouTube)

Dr. Catarina Esteves (TU/e)

Associate Professor Physical Chemistry, Department of Chemical Engineering and Chemistry, Eindhoven University of Technology

Associate Professor Physical Chemistry, Department of Chemical Engineering and Chemistry, Eindhoven University of Technology

Title: Design polymer networks for surface functionality: self-healing, anti-fouling and low-friction

Abstract

Surfaces play major roles in many different technologies, namely in catalysis, biomedical devices, solar panels or electronics. These applications performance can be highly improved by fine-tuning the surface with new functionalities such as anti-fouling, low-friction or self-healing behavior.

One way to achieve this is to apply a designed polymer layer, i.e. a polymer coating, with specific chemistry or surface roughness over the substrate or device. Crosslinked polymer networks are particularly interesting for this purpose. They provide the necessary robustness, cohesion and adhesion of the top polymer layer to the substrate; and they offer many possibilities to adjust the surface properties, via the use of different polymer precursors, crosslinkers and crosslinking configurations.

Functional polymer surfaces are, however, inherently dynamic and soft. They can rapidly change or be easily damaged by external factors resulting in reduced performance or complete loss of the surface related functions. Since surface damage can never be totally avoided the introduction of a self-healing mechanism is one way to repair the surface characteristics and maintain the materials function at high performance throughout an extended use period1.

Esteves, ACC et al. Self-healing functional surfaces Adv Mater Interf 2018, 5, 1800293.

In the recent years I have been interested in designing polymer networks to obtain surfaces with low or high surface energy, i.e. with (super)hydrophobic2 or hydrophilic3,4 character, which provide self-cleaning, anti-fouling or highly lubricious functionalities, respectively. Additionally, by the design of the polymer networks with a self-replenishing strategy, these surface functionalities can be recovered after damages1,5,6.

References for detailed information:

- Esteves, ACC et al. Self-healing functional surfaces Adv Mater Interf 2018, 5, 1800293.

- Esteves, ACC et al. Self-replenishing dual structured superhydrophobic coatings prepared by drop-casting of an all-in-one dispersion, Adv Funct Mater 2014, 24, 986.

- Jiménez-Pardo, I et al. Hydrophilic self-replenishing coatings with long-term water stability for anti-fouling applications, Coatings 2018, 8, 184.

- Albers, PTM et al. Design of dual hydrophobic-hydrophilic polymer networks for highly lubricious polyether-urethane coatings Europ Polym J 2019, 111, 82.

- Karasu, F et al. LED-cured self-replenishing hydrophobic coatings based on interpenetrating polymer networks (IPNs), RSC Advances 2016, 6.

- Esteves, ACC et al. Self-replenishing ability of cross-linked low surface energy polymer films investigated by a complementary experimental-simulation approach, J Chem Phys 2014, 140, 1249021.

Thursday 5 November 2020 (this session took place already)

15.00 - 17.00 hours

Speakers

Dr. Oded Raz (TU/e)

Associate Professor Electro-Optical Communication, Department of Electrical Engineering, Eindhoven University of Technology

Title: Programmable coatings for photonic integrated circuits - Presentation (Pdf)

Abstract

Programmable photonic integrated circuits (PICs) are a missing yes essential technology in order to fulfill the huge promise of photonics technology. A collaboration between the chemistry and electrical engineering departments has been investigating the use of polymers for the creation of novel programmable claddings for PICs which allow for low power and high programmability solutions.

Andriy Kuzmyn MSc (WUR)

PhD candidate Organic Chemistry, Department of Agrotechnology and Food Sciences, Wageningen University & Research

PhD candidate Organic Chemistry, Department of Agrotechnology and Food Sciences, Wageningen University & Research

Title: Visible light-triggered living polymerization for creating antifouling and bioactive surfaces - Presentation (Pdf)

Abstract (short version)

The visible light-triggered polymerization provides a new approach for creating antifouling polymer brushes. We have explored two methods for the creation of antifouling polymer brushes. In the first approach, hierarchical bioactive surfaces are formed by visible-light-induced surface-initiated living radical polymerization employing tris[2-phenylpyridinato-C2,N]iridium(III) as a photocatalyst. The second approach for the synthesis of antifouling polymer brushes using surface-initiated photoinduced electron transfer–reversible addition-fragmentation chain transfer (SI-PET-RAFT) polymerization with Eosin Y and triethanolamine as catalysts.

The full abstract can be found here (Pdf file).

Dr. Monique van der Veen (TU Delft)

Associate Professor Catalysis Engineering, Van der Veen Group, Department of Chemical Engineering, Delft University of Technology

Associate Professor Catalysis Engineering, Van der Veen Group, Department of Chemical Engineering, Delft University of Technology

Title: Metal-organic frameworks: nanoporous surface networks for selective sorption applications

The Van der Veen group is driven by the development of nanoporous materials for photocatalysis and electronics. "Most notably we works with metal-organic frameworks. These structures that consist of inorganic clusters linked by organic linkers into 3-D nanoporous crystalline solids offer a playground where via varying the constituents we can change the properties and topology at will. We focus on developping materials for converting solar energy into chemical fuels, to be used as memories in physically flexible electronics and to be used as harvesters of ambient mechanical vibration energy. An important component of our research is the use of advanced optical spectroscopy to gain detailed insight in the structure and function of nanoporous materials."

Dr. Kees Bastiaansen (TU/e)

Associate Professor Functional Organic Materials and Devices, Department of Chemical Engineering and Chemistry, Eindhoven University of Technology

Associate Professor Functional Organic Materials and Devices, Department of Chemical Engineering and Chemistry, Eindhoven University of Technology

Title: One-Dimensional Metals; some pro’s and con’s - Presentation (Pdf)

Abstract

Highly oriented and chain-extended natural and synthetic macromolecules are increasingly replacing metals and ceramics especially in applications where lightweighting is important such as in transport (automotive, trains, planes). Moreover, new optical, electronic and opto-electronic functionalities are being introduced into these systems. One the other hand, the one-dimensional character of these materials also imposes design restrictions and limitations which are also discussed.