Meet our Energizer! Peyman Taheri

Peyman Taheri, originally from Iran, earned his PhD in Materials Science and Engineering from Delft University of Technology, focusing on polymer-metal interfaces for corrosion inhibition. He subsequently held a postdoctoral position at the University of California, Berkeley, supported by a Rubicon-NWO personal grant, where he researched atomic-scale control of surface charge-transfer.

Photo: TU Delft

Today, Peyman Taheri is an Associate Professor in the Department of Materials Science and Engineering at TU Delft, where he conducts research in electrochemistry, surface science, and interface engineering for various applications, including electrocatalysts for energy conversion – particularly the electrochemical reduction of CO₂ and water splitting.

In 2024, he received a 4TU.Energy fund for the rapid development of a research idea ‘3D Printing Porous Electrode with Functional Coating for CO₂ Reduction’ together with dr. Davoud Jafari, University of Twente.

Contributing to the “carbon cycle”: transforming CO2 into synthetic fuel through electrochemical processes

Peyman explains his research by outlining his career steps. After completing his PhD, Peyman went to Berkeley to study surface science and engineering, but with a remarkably different application from the one he had worked on during his PhD. At Berkeley, he studied ultrathin transistors, which use the same fundamental science, i.e. surface engineering, to make devices, so it was an interesting venture. After his postdoc, Peyman joined TU Delft and moved to a new application area: Energy, and specifically the electrochemical reduction of CO2.

Peyman: “Reducing CO₂ emissions is a predominant strategy today – such as replacing fuel-powered cars with electric vehicles – to combat climate change. However, other approaches also exist. What interests me most is the process of capturing CO₂ directly from the air and convert it to synthetic fuel to reduce its concentration.”

Peyman goes on to explain: “The carbon cycle occurs naturally in the environment – consider, for example, breathing and photosynthesis as parts of this cycle. However, human activity has disrupted this balance. To help restore the cycle, we explore artificial methods to contribute to it, by capturing CO₂ from the air, dissolving it in an electrolyte and through electrochemical processes converting it into synthetic fuel.”

Redefining a costly but promising process

The process of converting CO2 into synthetic fuel is expensive. Peyman's research aims to make the process more economically viable. At the same time, the process is a highly multidisciplinary area of research, with physics, materials, electrochemistry and chemistry all playing an important role. Some of the current challenges in the conversion process are durability issues and the ability to produce a specific product at a fair price.

Peyman gives an example: “One example is the use of copper to convert CO₂ into synthetic fuels. Typically, this process produces a broad range of products, making separation both challenging and costly. However, through surface engineering of the copper catalyst, we can selectively produce formate as a single product, eliminating the need for complex separation and ultimately reducing the overall production cost.”

The multidisciplinary challenge of nanoscale material engineering

Engineering materials to design selective pathways for synthetic fuel production presents a range of challenges. Peyman explains: “One of the most rewarding aspects of this work is its multidisciplinary nature. We need a deep understanding of the material properties, but also the ability to assess how changes impact the overall process efficiency. This requires collaboration across materials science, chemistry, and physics, as well as process design and engineering.”

“As we tackle these technical challenges, we’re also aware of the need to increase the ‘technology readiness level’ (TRL) of our innovations. A common difficulty when working at low TRL levels is attracting industrial involvement, as the practical applications are not always immediately evident. We’re already part of several EU-funded projects with industry partners, but I’d like to see even more engagement to help bridge the gap between scientific discovery and industrial implementation.”

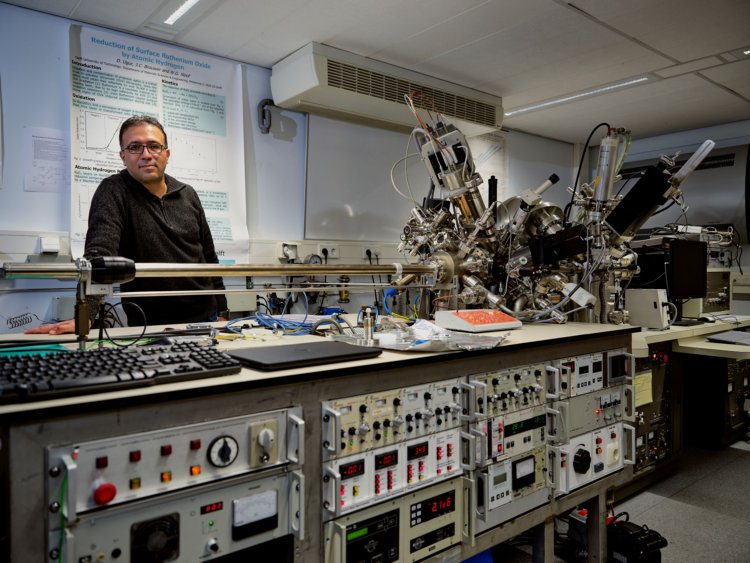

In the lab, Peyman takes a distinctly multidisciplinary approach to addressing materials challenges. He collaborates with colleagues who contribute computational modeling and has a keen interest in synthesis techniques. This approach extends to student selection: Peyman actively seeks students with multidisciplinary backgrounds, ensuring that project teams benefit from a broad range of expertise.

Picture: TU Delft

Opportunities for 4TU.Energy to expand coverage

Peyman has a positive outlook on 4TU.Energy: “I believe the 4TU.Centre for Energy is on the right track in bridging the gap between academia and industry. With the small amount of funding that my colleague Davoud Jafari and I received, we were able to quickly develop and test the feasibility of a new research idea.

What I think could be done in the future is to introduce more focus on different applications, different aspects of energy, and different clusters to organise focused meetings where we can look at how to involve industry at a very practical level.

For example, the catalyst community is huge and could be a sub-category within 4TU.Energy. I think this would broaden the scope of open calls for participation. I think there are more colleagues working on energy and contributing to the energy transition who are not yet involved in 4TU.Energy. There is an opportunity to involve them and get better connections across the board. I look forward to continuing to contribute to renewable energy in the long term.”

More about Peyman Taheri

Peyman Taheri is an Associate Professor in the Department of Materials Science and Engineering at TU Delft.

In 2024, he received a 4TU.Energy fund for the rapid development of a research idea ‘3D Printing Porous Electrode with Functional Coating for CO₂ Reduction’ together with Dr D. Jafari, University of Twente. Read the report of this project.

Personal website at TU Delft.