So how does a chemist speak to an industrial designer? Collaboration requires different vocabularies and information which the embedded designer needs to understand and develop. Creating novel soft devices requires new knowledge-transfer methods between disciplines. Soft robotics is an emerging field that involves constructing robotic functions from compliant materials which can exhibit specific behaviours, such as shape, stiffness and temperature changes. This makes them an ideal medium for interacting with the human body and allowing complex integration of sensors, actuators and control systems. However, to successfully develop new soft robotic functions for real-world applications, the field must become inherently multidisciplinary.

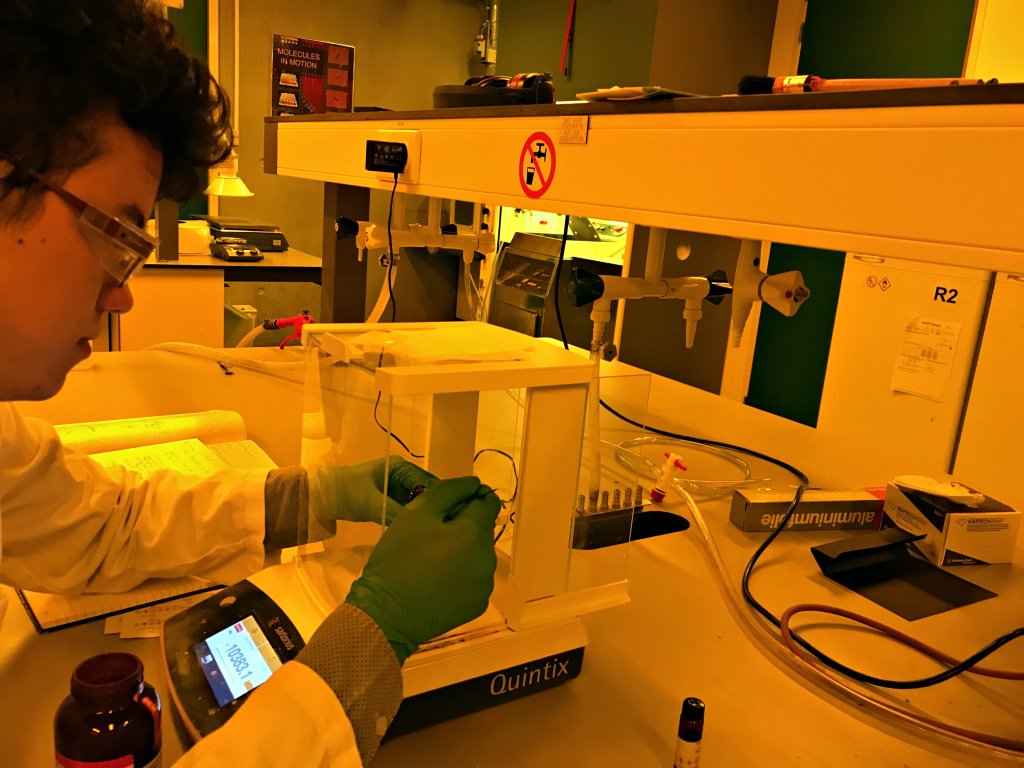

A team of TU/e chemists, mechanical engineers, and industrial designers worked together to apply thermo-active responsive fibers in the development of soft-robotic devices. Their aim was to bridge the gap between materials at a molecular level in material science in chemistry and implementation through soft robotic systems as well as developing a new cross-disciplinary language.

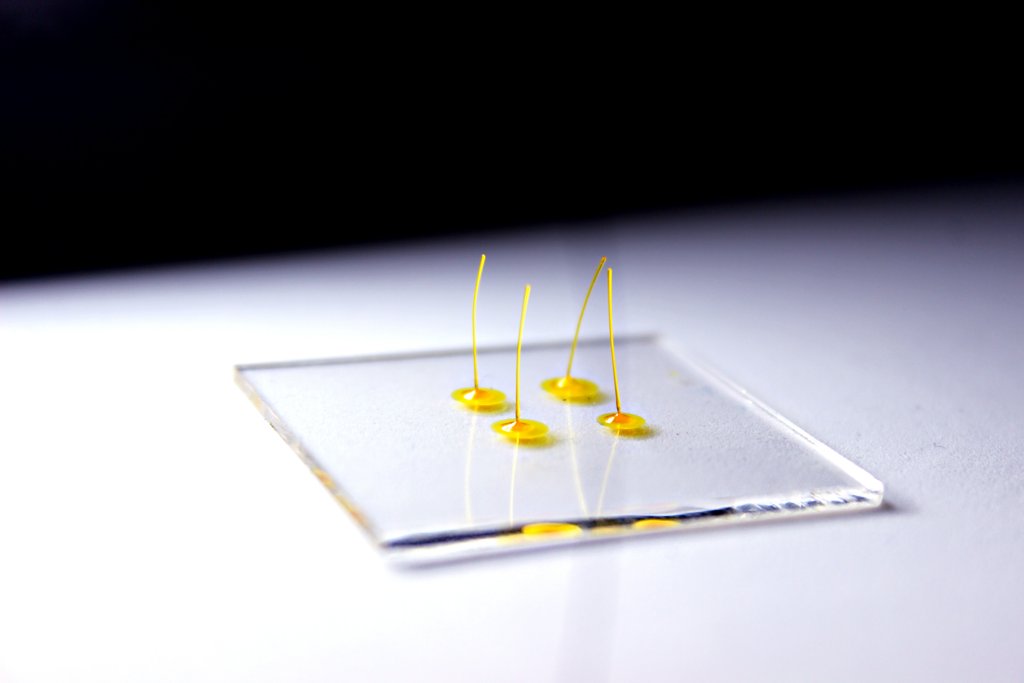

Dynamic Robotic Fibers drawn from liquid crystals can be individually addressed using a substrate patterned with electrodes, with the potential to create novel interactions between the device, the user and the environment.

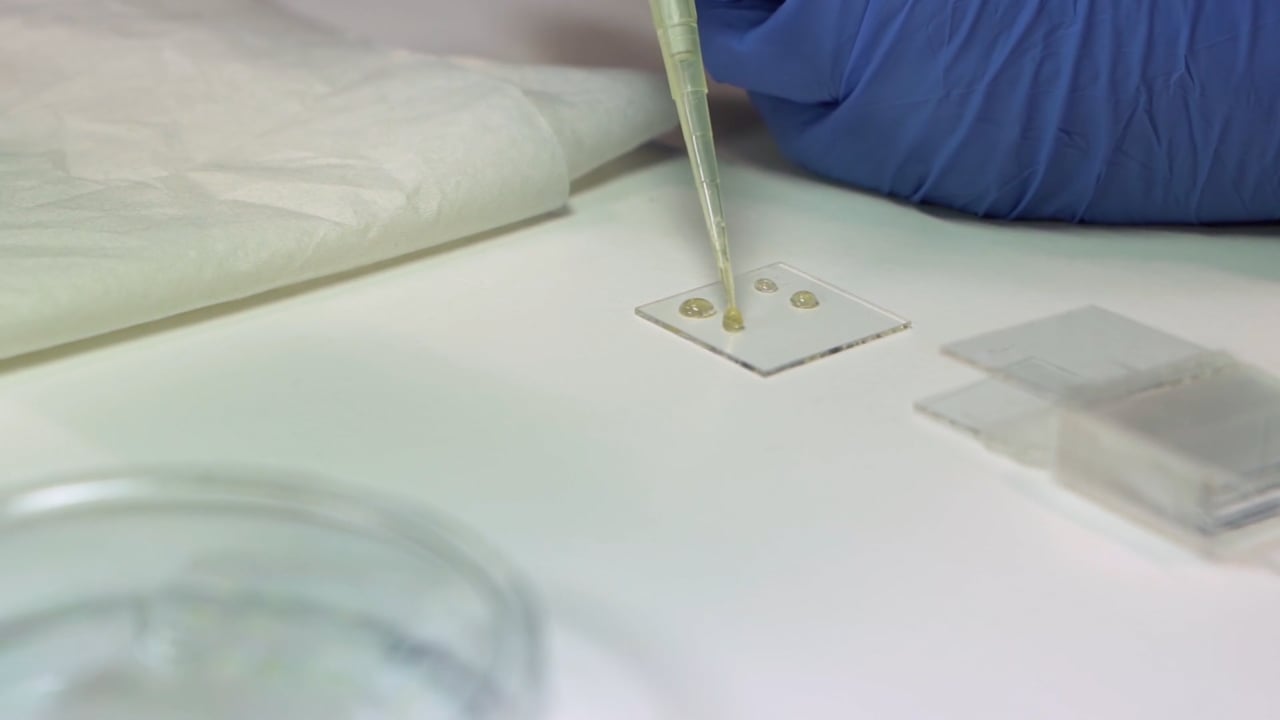

Fibers were created by attaching an upstanding fibre to a responsive base of a liquid crystal network working as an electricity-controlled heater. The team also devised a control system base for the fibre and developed a fibre drawing mechanism (FDM) tool.

The project was high-risk and experimental in that the fibers had never before been fabricated into a device. In this context, the team members had to become comfortable with ambiguity and uncertainty. To optimize the different expertise in the team, they used drawing and prototyping to develop a shared language with simple terminology and visual communication.

Integrating designers into scientific research teams at an early stage should become standard practice, and we foresee better knowledge transfer in two directions. The “embedded designer” can impact early-stage scientific R&D, enabling the rapid discovery of a critical link between molecular-level materials in material science and the implementation of soft robotic systems through HCI and Design. Likewise, the “embedded scientist” can impact the design process and device integration at a very early-stage.

When applied in collaboration with cross-disciplinary methods of working, collaborative languages in fabrication and novel design methodologies could enable the development of soft robotics value chains and unlock markets in the areas such as remote communication, haptics and healthcare.

Remarks

This project was an outcome of the challenge-based learning, cross-departmental masters course ‘Device Integrated Responsive Materials’.