Unito: products made from CO2

Unito draws inspiration from the natural carbon cycles of the biosphere to adapt our material production processes so that they result in negative carbon emissions, ultimately returning to a stable atmospheric carbon balance. In this project, we explore how the technosphere and biosphere could become interrelated to achieve a better balance with the ecosystems and climatic systems that we humans depend on.

Currently, nearly all the products we make result in carbon emissions and therefore contribute to climate change. But what if the act of producing a product could remove CO2 from the atmosphere? By using CO2 to produce materials, this possibility becomes a reality. Carbon-negative materials originate from atmospheric CO2. Typically, plant matter is converted into material through industrial processes powered by renewable energy.

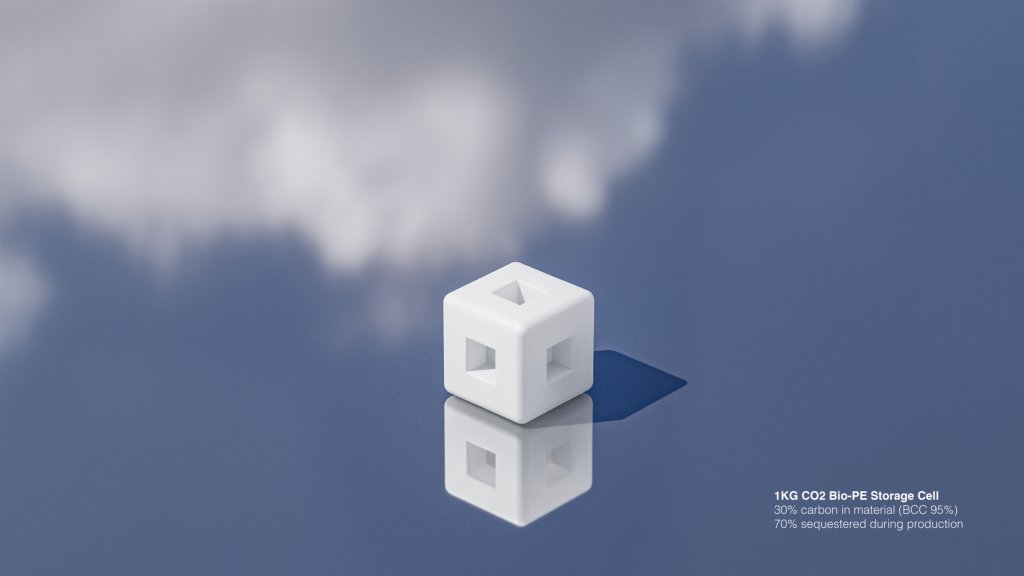

Because these materials are made from CO2, they store carbon. Throughout the material’s life cycle, it acts as an artificial carbon sink, enabling excess CO2 in the atmosphere to be removed and stored in a functional way. By considering carbon storage as a design driver, this project imagines what products derived from CO2 might look like.

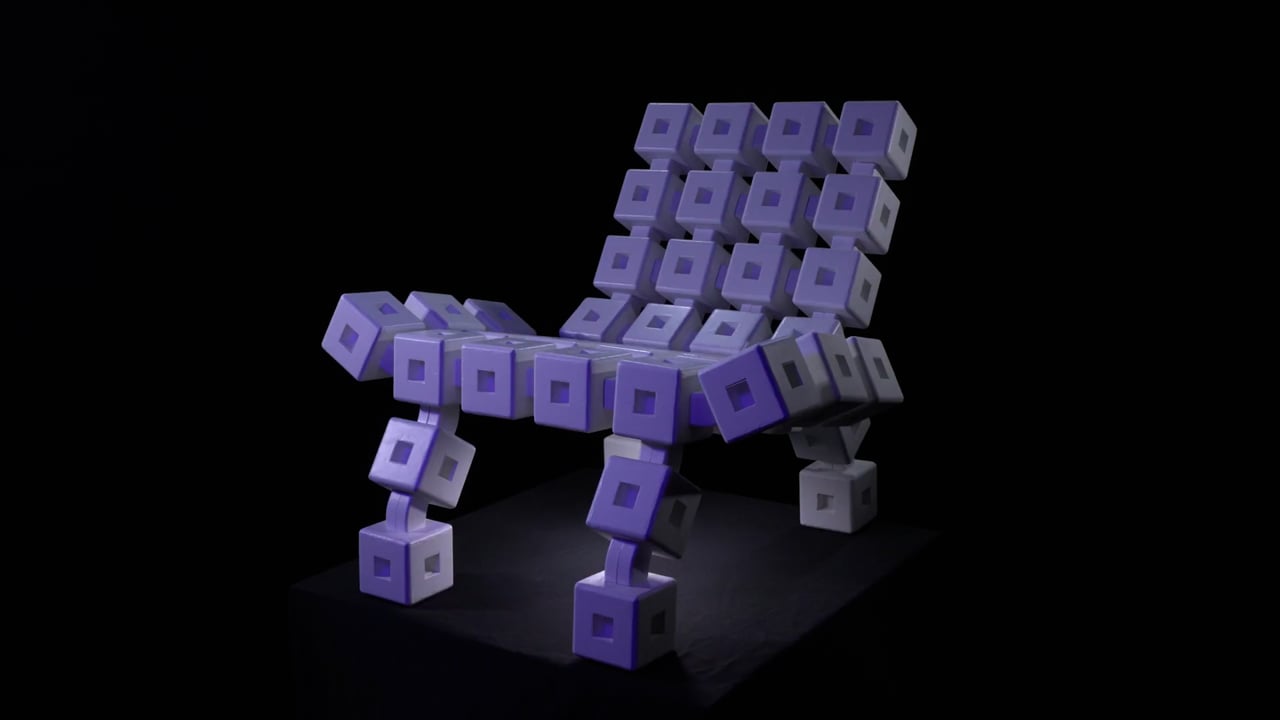

If products are created from CO2, they act not only to fulfill a function but also to store carbon. This adds a new dimension to product design. Four Unito design drivers are postulated to optimize products for carbon storage:

- Products should be made from materials derived from CO2 feedstocks.

- Products should maximize CO2 storage

- CO2 should remain stored in products for as long as possible

In Unito, carbon is stored in functional modular structures designed to last for hundreds of years, reconfigurable into new products in anticipation of changing human needs.

The modules are made from bio-HDPE derived from sugarcane, with a negative carbon footprint. Each unit contains 1kg of organic carbon. The material is also recyclable, i.e. the carbon can remain trapped in a circular material system at the product’s end-of-life.

The project’s goal is to illustrate to the wider design world the incredible idea of Carbon Dioxide Utilization (CDU) in materials. While a specific material candidate is showcased in the product (Bio-HDPE), this reimagining of our material-product systems has the potential to be scaled-up across the economy, given the wide array of carbon-based materials. In fact, anything derived from carbon can be made from CO2.

New materials, processes, and improvements in efficiency, coupled with a drive to decarbonize large sectors of the economy will make this concept a reality in the coming decades. The CDU approach is imperative for CO2 sequestration and harnesses our human instinct for consumption and growth, but in a way that addresses the climate crisis.

Share

Contacts

- -Riel Bessai

- -Ruud Balkenende

- -Erik Jepma