Soft robotics present both a compelling opportunity and novel challenges for the Design and Human-Computer Interaction (HCI) community. Advanced material actuators can be fabricated through multiple forms and new soft bodies (e.g., coatings or structures), enabling the transfer into everyday materials. However, we are yet to fully realize their dynamic and expressive potential beyond tethered approaches such as pneumatics and motors. Can Design transform Advanced Materials into Interactive Matters?

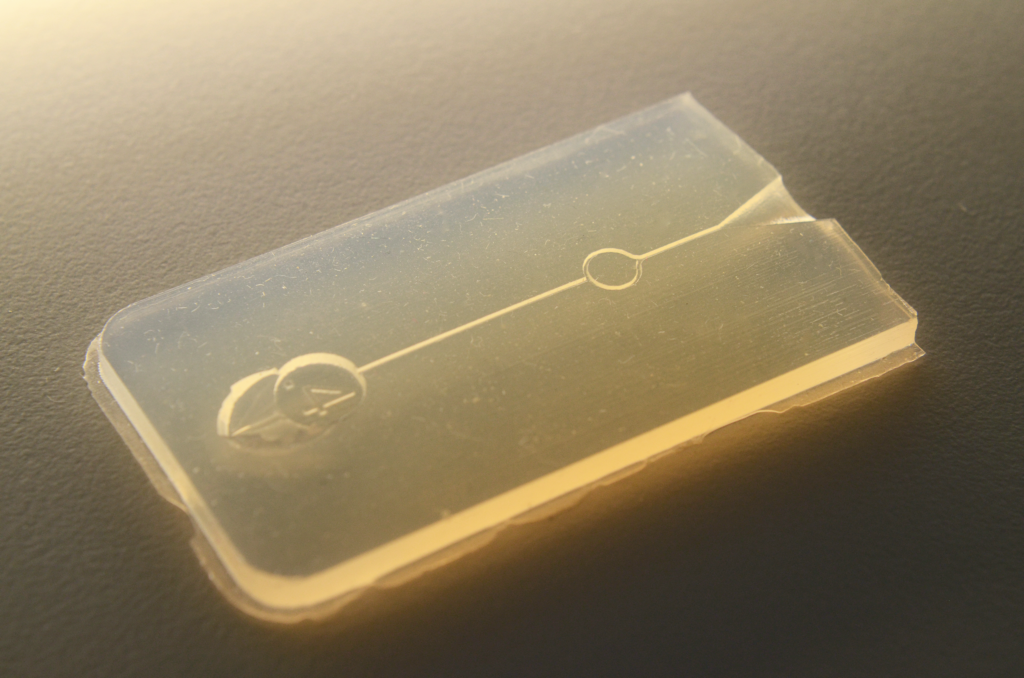

Our work aims to bridge this gap by supporting the design of soft robots through a case study of electro-thermal actuated Liquid Crystal Elastomer (LCE) Fibers. LCEs are a unique material for Design and HCI that may improve the features of shape-changing interfaces (SCIs) and soft-robotic mechanisms through time-varying shapes in more nuanced, controllable, and programmable ways.

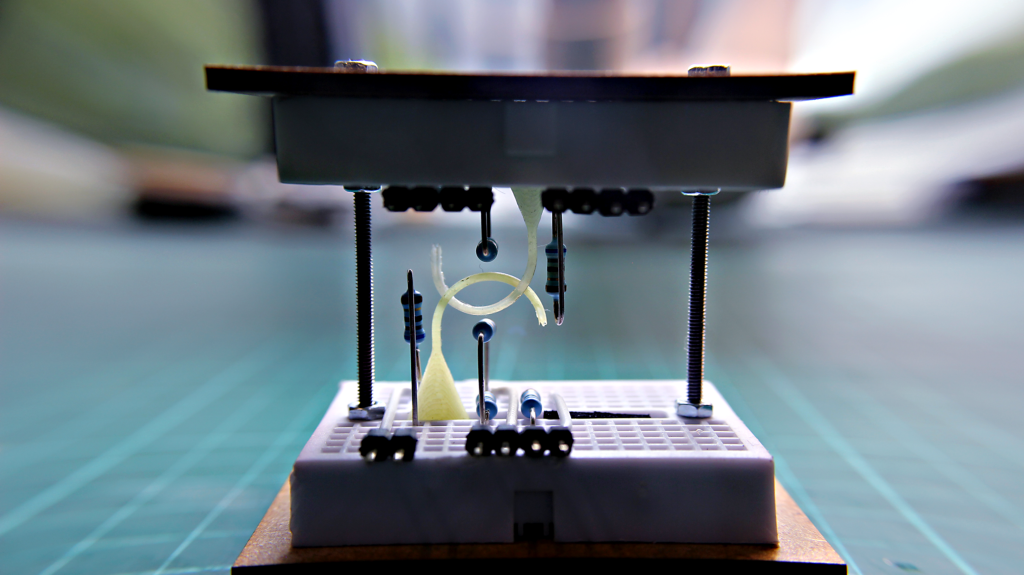

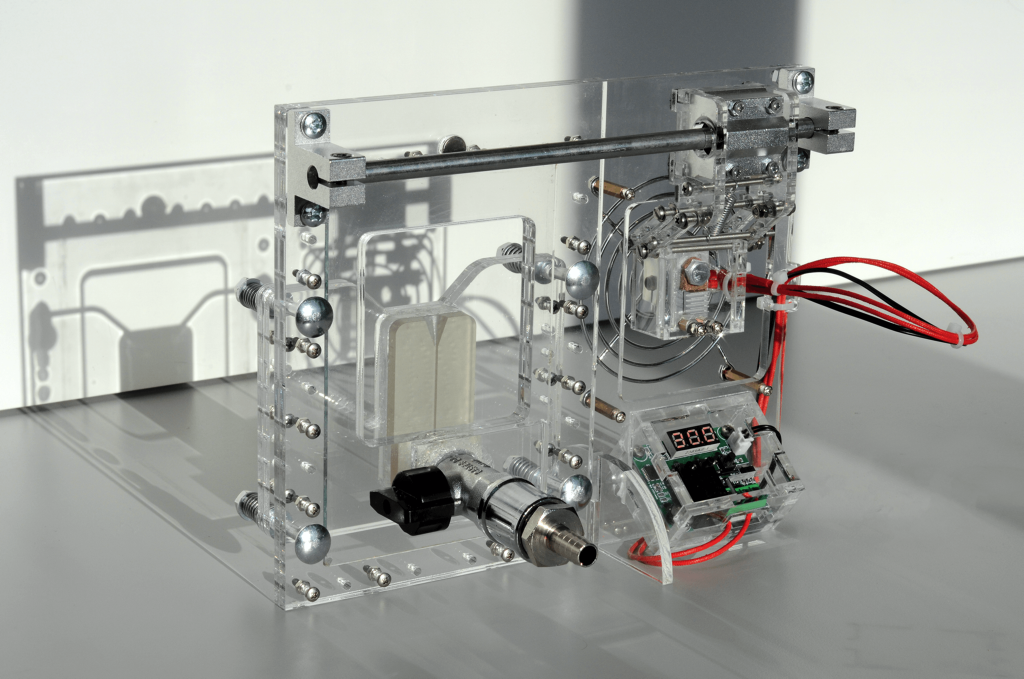

We propose a three-level strategy called "Material Programming" that facilitates the integration of advanced materials into soft robotic devices by programming LCE fibres through changes in morphology, movement and timing. Firstly, changes to morphology are achieved through a custom-built open-source vacuum moulding machine. Secondly changes to movement are achieved through heat source configurations with an Arduino-controlled system and processing interface. Lastly, changes to timing (motion sequencing) can be achieved through Choreographer UI. Our design strategy envisions how Material Programming can be applied as a method towards developing soft robotic systems, as well as the value of working at a multidisciplinary level across Material Science, Robotics, Design and HCI.

We created a new methodology for advanced enabling technologies via hands-on experiments with fabrication, mechanical, and digital I/O control at the intersection of material science and industrial design. Designers can experiment with fiber shapes to enable tailored behaviours in novel interactive applications, from soft actuators to adaptive textiles.

The Material Aesthetics Lab Department of Industrial Design, TU/e

Stimuli-responsive Functional Materials & Devices, Department of Chemical Engineering and Chemistry, TU/e