3D Woven Denim jacket

Barbara Vroom & Sterre de Jager, Holly McQuillan, Eleni Soerjo, Ingrid Mulder, Diamond Denim by Sapphire, Milou Voorwinden, Mohsin Sajid

Can we manufacture fashion sustainably using 3D weaving?

Current denim production is marked by complex global processes, with profound ethical, environmental and societal consequences. For 150 years, the aesthetics and production of denim have hardly changed. This stagnant design approach results in a staggering 15% fabric waste per garment, raising a pivotal question: should we not embrace novel denim aesthetics with alternative design, manufacturing and systems?

This 3D weaving research project reimagines the manufacturing of a denim jacket. We 3D weaved seamlessly integrated woven textile designs, employing multi-layer textile structures. This significantly reduced post-weaving production steps and the associated cutting waste, paving the way for a more sustainable future.

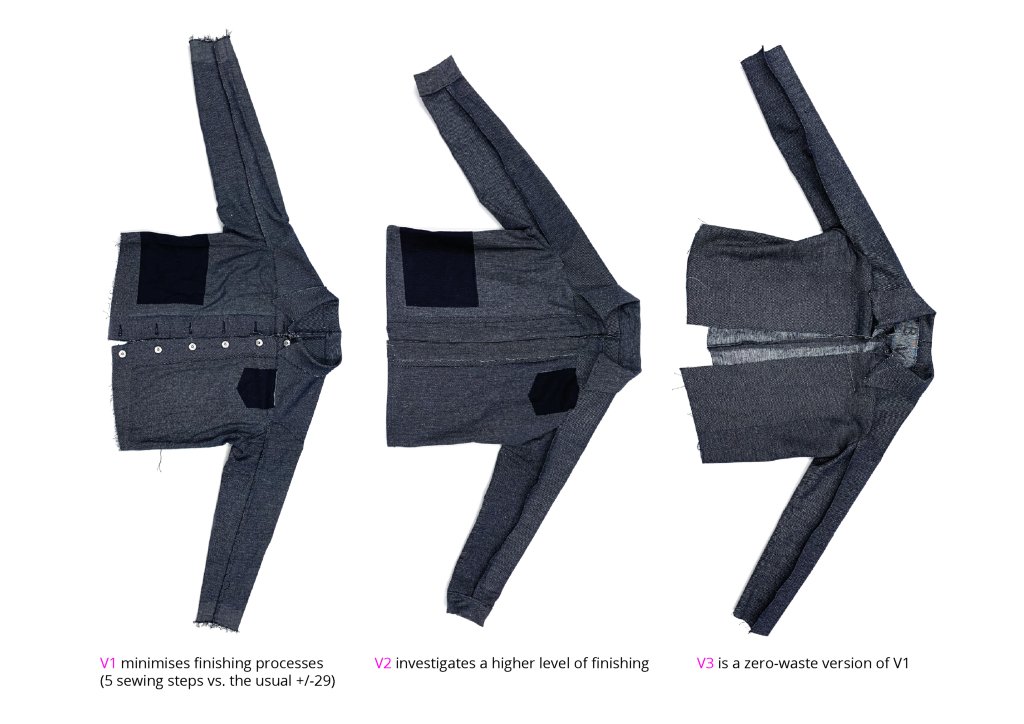

We explored reducing the pre-consumer waste associated with traditional denim jacket manufacturing while maintaining the emotional and physical durability expected by the user. Three versions were developed to investigate different design variable: v1 minimised finishing processes -5 sewing steps vs. the usual +/-29; v2 investigated a higher level of finishing; and v3 was a zero-waste version of v1. The denim jackets were made with existing machinery (a loom), but its capabilities were adapted to enable multi-layered weaving.

Changes in the manufacturing process raise the question whether the 3D woven denim jacket can and should look the same as traditionally woven denim. We show how and to what degree this similarity can be achieved. Moreover, 3D weaving permits micro-manufacturing, supporting the future relocalisation of supply chains and the creation of new, sustainable fashion systems.

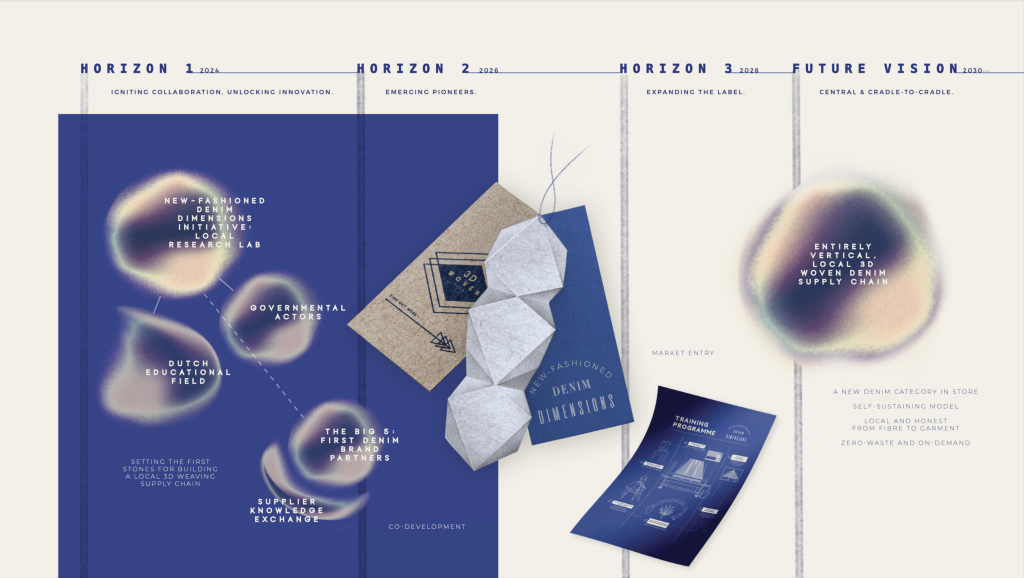

3D weaving a denim jacket illustrates the promise of a holistic approach to fashion design, supporting the pursuit of zero waste and streamlining supply chain procedures. This project emphasizes the challenges and possibilities of 3D weaving as well as the negative effects of the current paradigm on designers and business. In order to transition to a new local supply chain, align user acceptance of new aesthetics, and redefine design responsibilities, we proposed a systems-oriented strategy for the Netherlands. We identified key Dutch actors and actions, proposing a systems-oriented strategy, including tool-building, training programs, and traceability systems. The ultimate goal is to stimulate novel industry-wide design approaches beyond 3D woven denim.

Instagram: @3DWovenDenim

#denim #3DWeaving #3Dwovendenim #denimjacket #zerowastedesign #zerowaste #sustainablefashion #sustainabletextiles #sustainability #designresearch #textileresearch #weaving #textiledesign #fashiondesign #collaboration #industrialweaving #jacquard #multilayerweaving #futurefashion #weavinginnovation #deniminnovation #systemorientedstrategy #dutchdenim #dutchdenimsystem #systemicdesign #textileform

Share

Contacts

- -Barbara vroombarbaravroom@xs4all.nl

- -Sterre de Jager