3D printing is an innovative production process that can support design in a circular economy. In a circular economy, high-value material recovery is required to enable multiple product lifecycles. Furthermore, materials need to be developed that are derived from bio-based and abundant resources as an alternative for oil-based materials. Therefore, not only the material resource is important when developing materials for 3D printing in a circular economy, but also the recovery options. That is what inspired the development of reprintable materials. These are materials made from renewable resources that can be recovered into ready-to-print materials after a 3D printed product becomes obsolete.

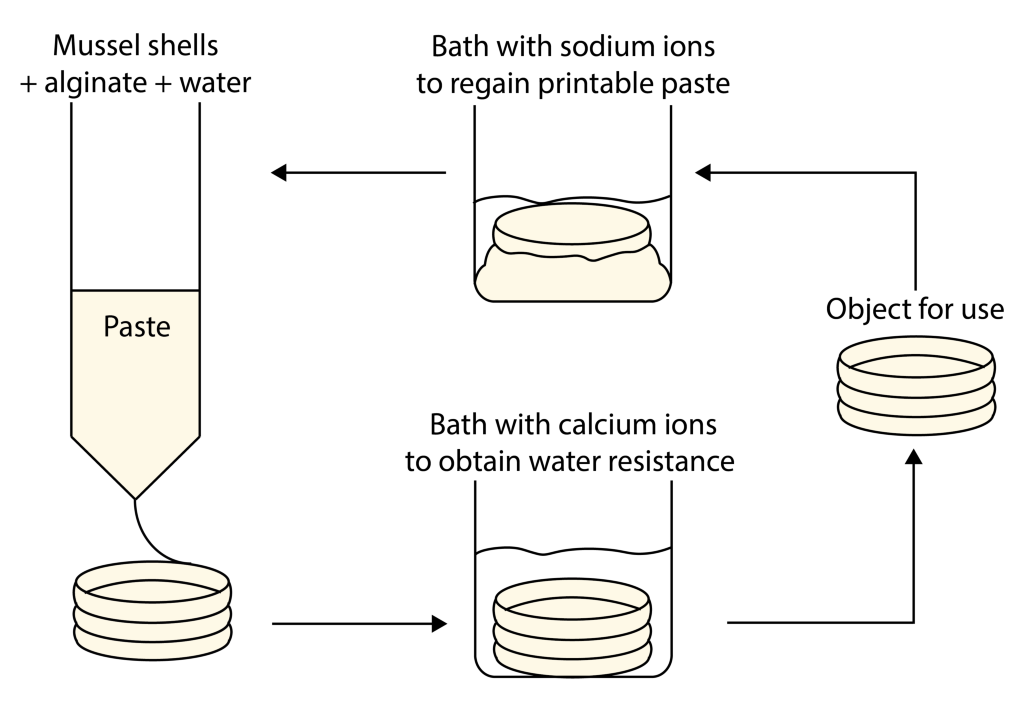

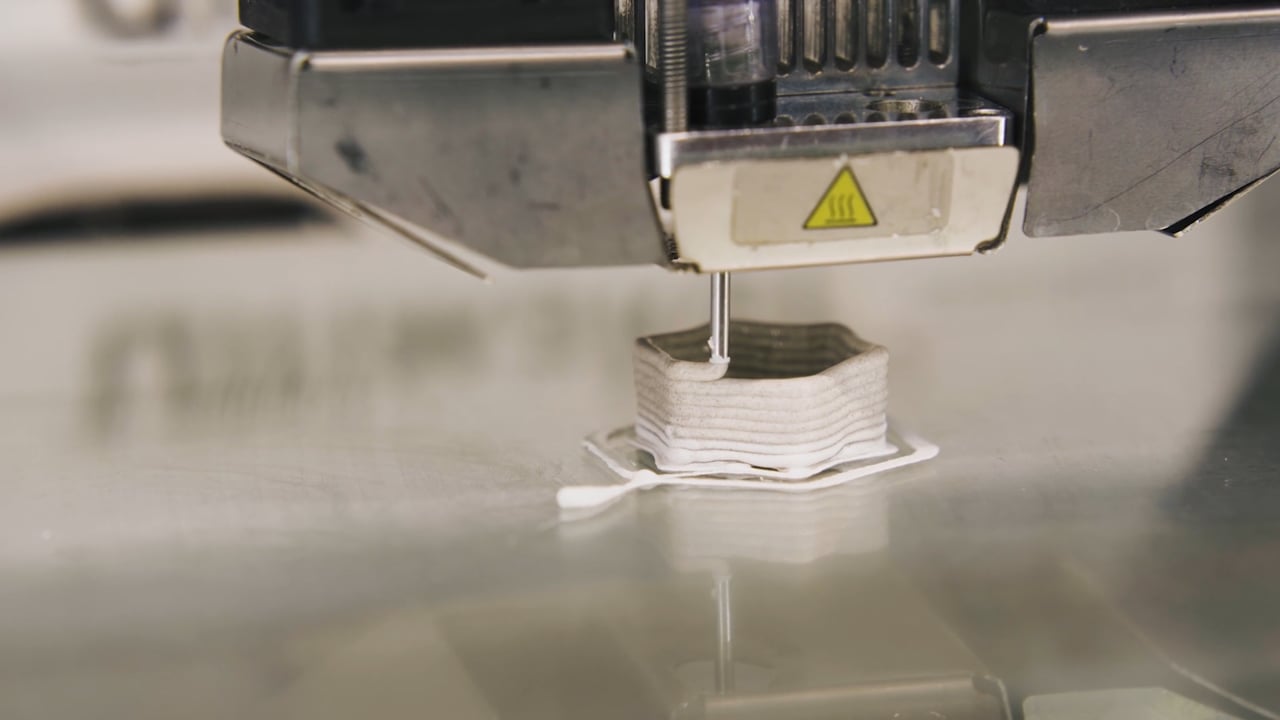

To achieve high-value and high-quality recovery, it is important to take a system perspective and therefore a design approach was used to develop reprintable materials. Materials for 3D paste printing were developed from ground mussel shells and alginate. Ground mussel shells are a large waste stream in the Netherlands and alginate is a binder that can make the material water resistant for use and be returned into a printable paste after use.

An object can be made water resistant by placing it in a calcium bath after printing and drying. Once the object becomes obsolete, the material can be mixed with a sodium solution to dissolve for paste printing. A special property of this material is its change of property after submersion in water: when dry, the material is rigid; when wet, the material becomes ductile. This inspired the design of a hairpin which was printed flat and bent afterwards to follow the curve of the head.

In designing for a circular economy, we have to care for our materials and think about how they can return. This is also important for bio-based print materials as we take them from the ecosystem to use them in our man-made world. We put energy in them to increase their value for our use and so we should keep that value as high as possible for as long as possible before safely returning them back into the ecosystem. Reprintable materials care for their resources as well as their recovery. This causes a new kind of behaviour that triggers us to consider the material in all its entities and to value its properties.