Design researchers are exploring new opportunities for using emerging materials, human-machine interaction, digital craftsmanship, and new production systems. Currently, the flow from one machine to another remains a challenge in terms of workflow, communication, orientation, and material. Efforts have been made to combine fabrication machines into a single workflow, but there is little cross-pollination between techniques. In this project, researchers worked closely with a wide range of digital fabrication technologies, like 3D printers and digital embroidery machines to explore how to better facilitate the communication between digital fabrication machines.

Exquisite Fabrication is an approach to digital fabrication that aims to foster exploration, improvisation, and cross-pollination of techniques.

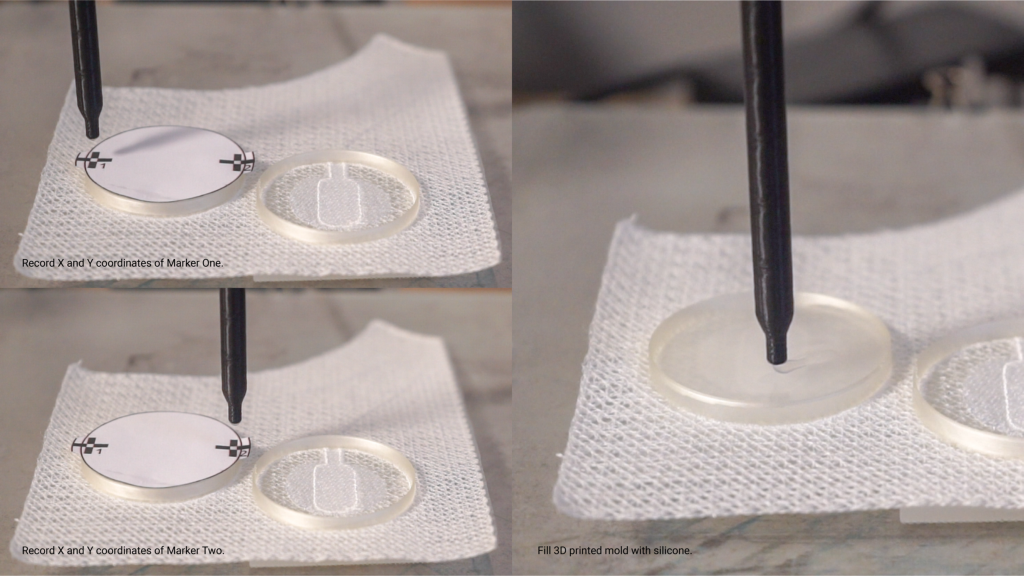

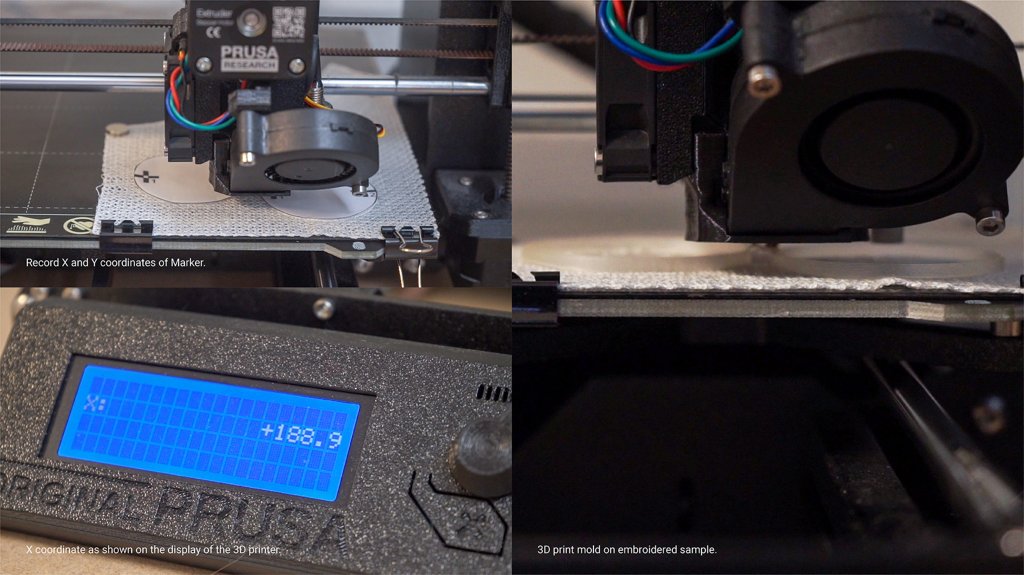

Inspired by the surrealist art game of Exquisite Corpset designers and machines take turns in the making process, focusing only on the points of transition between fabrication stages. To support this approach, we designed a Machine Operation Alignment System (MOAS) that provides starting points for machines, and we developed guidelines for ways in which different digital fabrication machines and designers can collaborate. Exquisite Fabrication encourages designers to explore whether to include, exclude or replace machines while the production systems they interact with remain flexible. As a demonstrator, we used MOAS to provide starting points to fabricate a textile sample based on an inflatable actuator. The fabrication of this sample took four steps, using three different machines, supported by two designers.

We show that engaging in Exquisite Fabrication can be valuable when designing bottom-up processes, allowing decisions to be made based on the real implications of current production systems and facilitating the creation of flexible systems of production. MOAS can be directly applied to existing production systems, making it quick and easy to explore new methods of fabrication using emerging technologies.

When a new digital machine comes on the market with new functionality, this machine can be more easily incorporated into the making workflow without having to be fully compatible with existing machines.