The Dutch healthcare sector accounts for 7% of the country's national carbon emissions and 13% of material consumption. Single-use medical devices contribute significantly to this burden. Inflators are a major example. They are essential in interventional cardiology and radiology to restore blood flow to blocked blood vessels. They must withstand 25 times more pressure than standard car tires. Annually, around 100,000 inflators are used and incinerated after use as they are considered contaminated. Current inflators cannot be disassembled, so they cannot be reused.

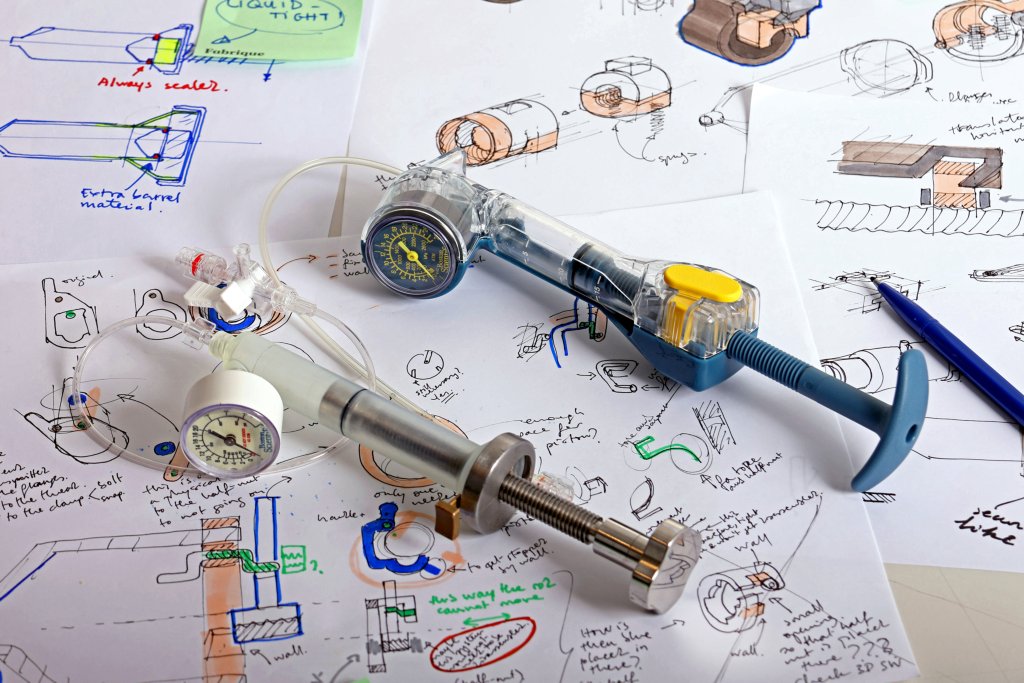

POMPA is a circular redesign of these single-use inflators. It focuses on the reuse of the most valuable components within healthcare institutions while disposing of the rest. It has been made possible by involving clinicians, decontamination experts, and engineers throughout the design process and validation of the proposed solutions. This participatory design led to a redesign of the inflator’s architecture that is intuitive for doctors, guarantees clinical performance, and enables disassembly and reassembly in under a minute, making decontamination and safe reuse possible.

Its reusable components integrate into hospital decontamination workflows and withstand the high-pressure use and sterilisation cycles. All reusable components are made of stainless steel 316L, except for the transparent barrel, which utilises PEI to prevent air bubbles or blood from entering the fluid, and the nitinol spring mechanism, which has already been CE-certified for use in reusable medical devices.

POMPA leads the shift from single-use to reusable medical devices to achieve a more sustainable healthcare sector. It is the first non-single-use inflator, the first that can be disassembled without breaking, and the first that allows reuse within hospitals by adapting into current decontamination workflows. It has a lower environmental and economic impact than current inflators after only 9 uses, and its reusable components can be reused for up to 1000 procedures.