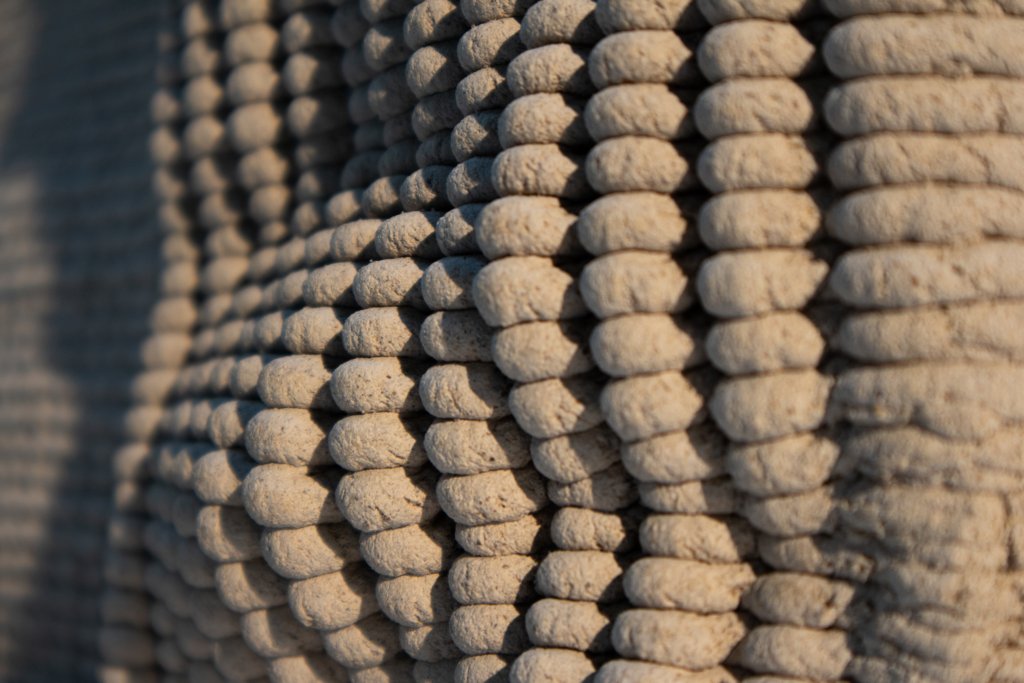

In Controlling Roughness, we explore the roughness of a bio-circular material as a design feature controlled through a 3D printing process. Through experimentation, we demonstrate how surface roughness is dependent on 3D printing parameter variations. By measuring the absorption coefficients, we show that these parameters can be modified to influence the material’s acoustic properties. The outcome is a set of blocks that contrast in acoustic absorption; from none to very pronounced parameter variations.

What if buildings could sound different due to how they’re printed?

Direction & Editing : Marica De Michele

Director of Photography : Jurica Marković

Music : Ivna Jurković

Production Assistant : Clara Gustafsson

Bio-circular materials provide a smaller embodied carbon footprint, answering the need for more sustainable construction practices in architecture. Nevertheless, these materials are more complex to handle compared to standard industrialized materials.

In Controlling Roughness we show that these materials can be manufactured in such a way that defines their competence, giving them a place in the architectural context, and unwrapping new design opportunities. We implemented a material recipe by Studio Omlab. With this material, we investigated how 3D printing can be leveraged to enhance the unique roughness of the material.

Through a series of experiments, we demonstrate that surface roughness is influenced by modifying 3D printing parameters.

Architectural acoustics are a design problem highly influenced by wall surface treatment. Accordingly, we studied the relationship between surface roughness and acoustic performance.

By measuring the absorption coefficients of different specimens, our findings reveal that 3D printing parameters can be modified to influence the material’s acoustic properties.

As an outcome, we developed a set of blocks using a bio-circular material which demonstrate a contrast in acoustic absorption ranging from none to very pronounced parameter variations.

Controlling roughness shows that additive manufacturing enables the design of multi-scale surface roughness that influences acoustic performance. This opens new pathways for 3D printing with bio-circular materials in architectural contexts. In this way we position roughness as a controllable asset to meet architectural needs.

#bio-circularmaterials #3D-printedarchitecture #acoustics