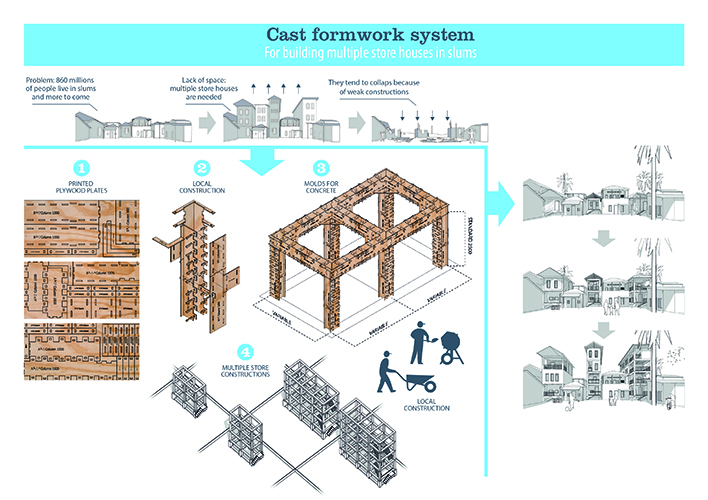

CAST Formwork Systems (CFS) is a concrete formwork system based on CNC milling technology. It enables self-construction in informal areas to build up safe, incremental housing up to four storeys high. Ordinary formwork systems are complex to use, often too expensive for the low- to mid-low income group and only suited to one shape of building plot. The CFS-system is not only cheaper, it can be customized to all shapes of building-plots and is both safe and easier in use.

The problem

We live in an urban era; the Global Health Organization estimates that in 2050 almost 75% of the world population will live in cities. The biggest urban growth will take place in ‘informally built parts of the city’, often known as slums. These areas are formed when the government can no longer deal with the rapid growth of the urban population and city inhabitants start constructing their own living quarters. While densification in these ever growing mega-cities is sorely needed, the inhabitants often lack the building knowledge needed to construct safe housing over two stories high. Dangerous situations occur since these self-constructed houses are often not able to withstand the earthquakes and yearly flooding these poorly situated areas are exposed to.

The goal

The immediate objective is to provide a safe building method in the informal areas of Indonesian cities. These informal areas are called ‘Kampung’ and are an excellent example of self-build areas, 80% of Indonesian cities consist of these kampungs. They are more than just places to sleep, these Kampung thrive on a very close knit community and are full of economic activities. A governmental top-bottom approach in handling these areas often consists of tearing down the whole Kampung and build high rises in its place. This ‘block attack’ destroys not only the community but also denies the city inhabitants their economic opportunities. The CAST Formwork System proposes a bottom up approach where the inhabitants can independently build up safe housing in accordance with local practice.

Origins

The company CAST Formwork System (CAST) came forth from the thesis ‘Tra-Digital Hybrids’ written by Nadia Remmerswaal. In July 2015 she graduated from the Faculty Architecture at TU Delft as best graduate of her year with this thesis. In her graduation project, she delved into enabling safe, self-build constructions in informal neighborhoods, the Kampungs of Bandung, Indonesia.

The formwork is specifically designed for self-build areas, to be used by residents themselves.

Research shows that 80% of the build environment of Indonesian cities is self-build, in Indonesia this results in 100 million Kampung inhabitants, and it is expected that before 2050 we will see 50 million more Kampung inhabitants. This enormous city growth is not limited to Indonesia, but will happen in mega-cities worldwide. These DIY areas are prone to earthquakes and flooding, and residents often do not have enough building knowledge to build sustainable structures to withstand these natural disasters. After witnessing this in the cities of Indonesia, Remmerswaal tried to find a technical solution in her architectural graduation to enable safe self-construction in these areas.

After graduating Remmerswaal sought funding in the form of scientific financing and participated in several competitions to develop the project further. The project won the ASN Bank World Prize

“Veiligheid & Sociale cohesie”, prize money €8000, the STW Open Mind funding, €50,000 and the 4TU Lighthouse funding, €50,000. The project has been renamed ‘CAST Formwork System’, CAST an abbreviation of ‘casting concrete’ and Remmerswaal started developing the project in February 2016. The objectives of the project are to create both a workable prototype and a workable revenue model. Both are be completed in February 2017 when the project financing ends.

The technique

CAST Formwork System is a formwork system based on CNC milling technology. The CAST system makes up the mould in which the concrete can be cast. The resulting concrete frame forms a durable structure and safe concrete skeleton. The formwork is specifically designed for self-build areas, to be used by residents themselves. The system is made from special wood: Betonplex, this hardwood triplex has a smooth, very durable coating that makes de-casting the formwork easy. Betonplex is being produced locally in Indonesia. The elements are never bigger than 1,5 meter, and can be easily transported into the Kampung using a handcard. It is designed to be as simple as possible, so that it can be put together by people with limited construction knowledge.

After the assembly of the formwork, the concrete is cast and when dry the formwork can be reused a minimum of 8 times. Normal formwork systems are often complex to use, need cranes or trucks to be transported or assembled, are too expensive for the low to middle-low income group in self-construction areas and only suitable for one form construction plot. CAST strives to be an inexpensive alternative that is easily adapted to multiple building plot configurations. Since not a single house in the Kampung, or self-build areas around the globe for that matter, are equal, this is an essential important aspect of the system.

With CAST Formwork System it is safe to build up to multiple levels, right now this is often impossible, inadequate construction knowledge prevents the buildings to reach over 2 building stories. With the CAST-system, it would be possible to expand the dwelling in an incremental manner: the first year the foundations and first story is constructed, and when inhabitants have gathered sufficient funding a second story can be constructed several years on. This incremental building method is essential as these informal neighborhoods often lack the financial resources to construct a four-story house all at once. This incremental construction method makes it possible for a household to spread the investment over several years.

A concrete frame of 3 x 7 x 3 meter was realized within two weeks.

The next step

In December 2016 a CAST-Formwork prototype has been tested at the Green Village in Delft. A concrete frame of 3 x 7 x 3 meter has been realized within two weeks. While some technical adjustments have to be made, the team considers the test a great success. The next step is to do more local testing in Indonesia in January 2017, and to present the formwork at the ‘Week van de Bouw’ in February 2017. A pilot project is being developed in Bandung Indonesia, if sufficient funding is found, 6 pilot homes will be built with the CAST Formwork System in May 2017.

Team:

Delft University of Technology

ir. Nadia Reimerswaal, Dr.-ing. Marcel Bilow

Eindhoven University of Technology

Dr.ir. Faas Moonen, ir. Rijk Blok

Jongeneel

Cementbouw

Van Gelder

GreenVillage

Riset 8 kota Indonesia